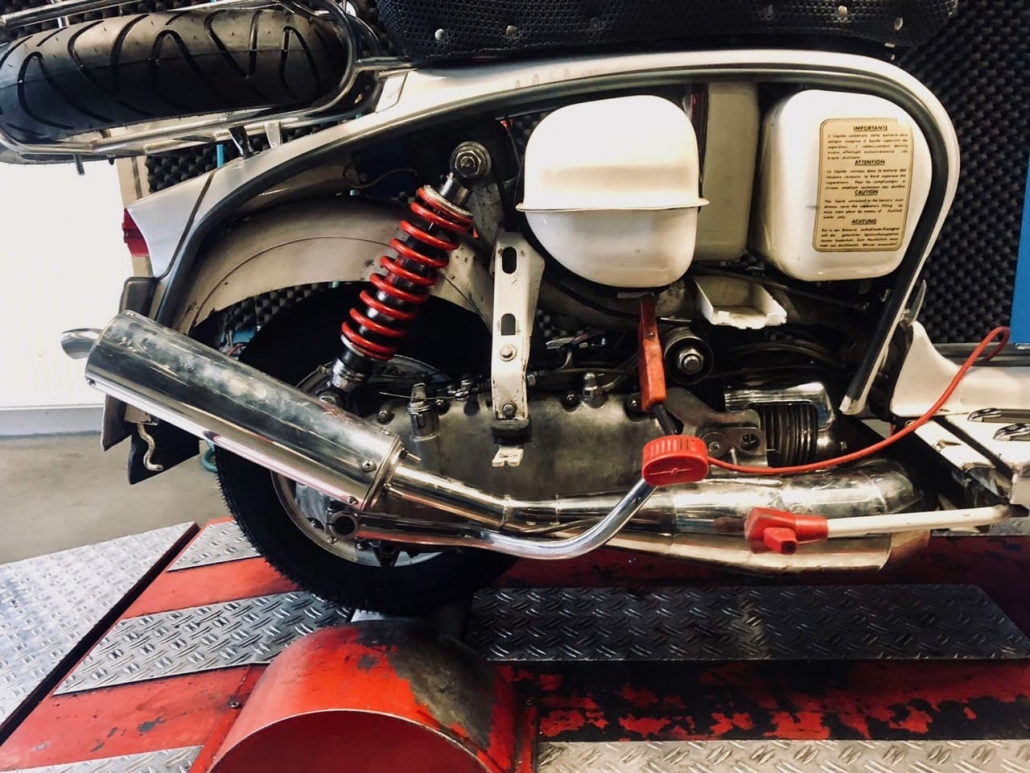

Lambretta expansion chamber and big box Clubman prototype test

Lambretta exhaust test, while the new and upcoming Lambretta Big Box is currently in production. Unfortunately, a delivery date is still unknown.

Lambretta exhausts onthe dyno

Before we have send the final sample to Spain, we put the new box through its paces. Additionally we have another prototype box from our friend Chalky from Replay Scooters and JPP on the dyno:

- bgm PRO BigBox Proto

- JPP Box Proto

The following expansion chambers competed against the boxes:

- the TSR Evo,

- the JL3 and

- in MB3

And all three reso systems did better against the boxes than we would have expected!

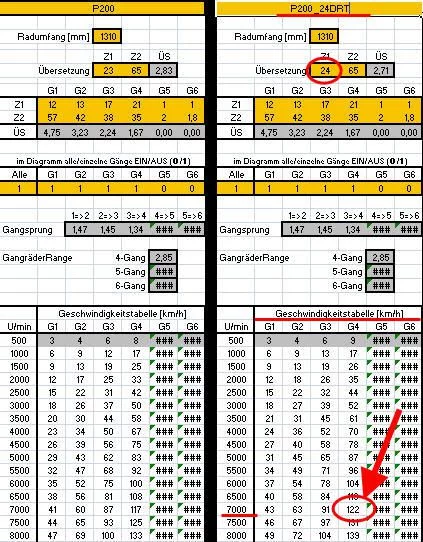

The Lambretta engine

The test engine was constructed as follows:

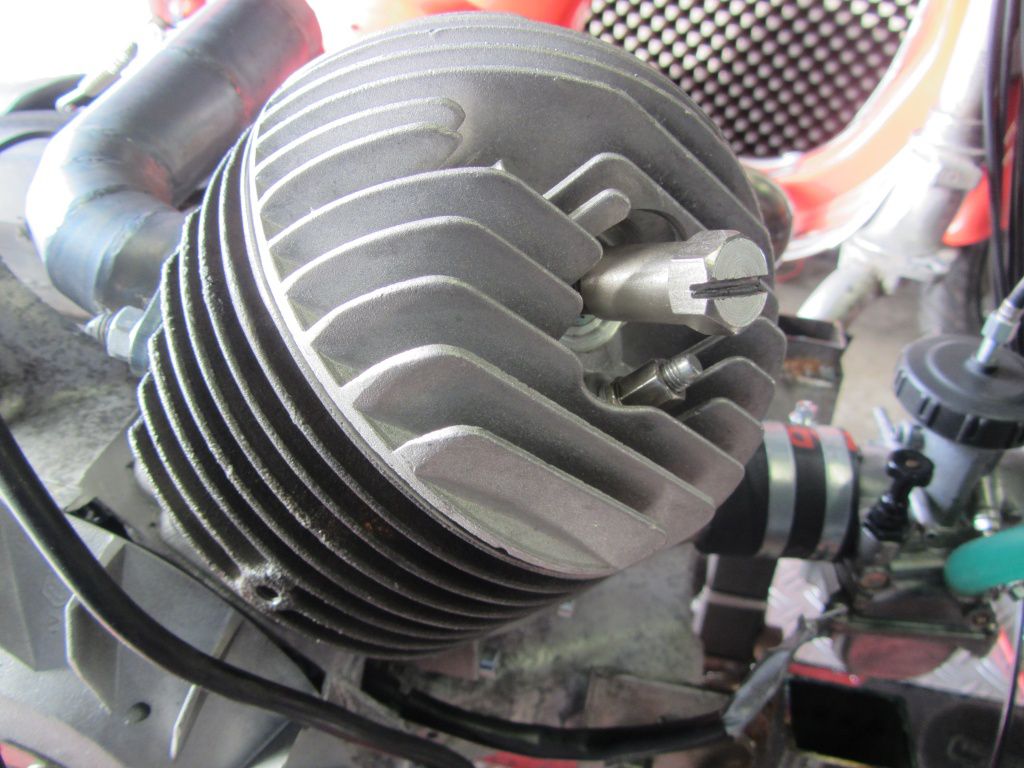

- Cylinder: RT225 cylinder converted to reed valve (BGM2225NR)

- Crankshaft: bgm PRO 110/60 (BGM11060N)

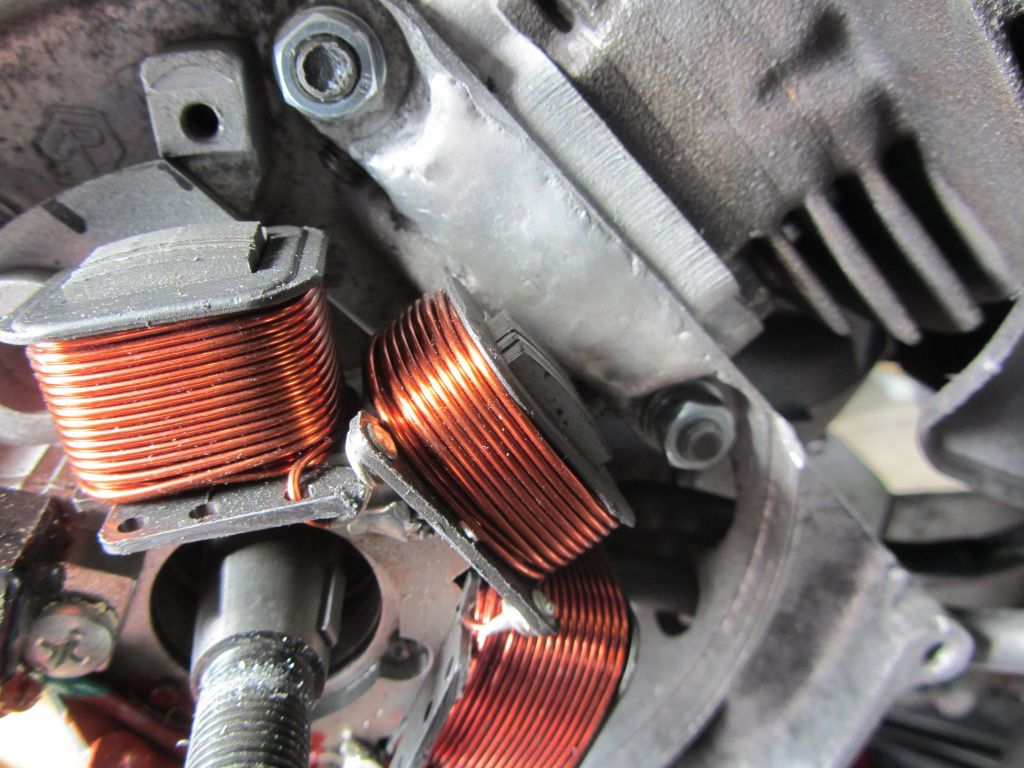

- Ignition: bgm PRO electronic AC ign ition (BGM210900KT)

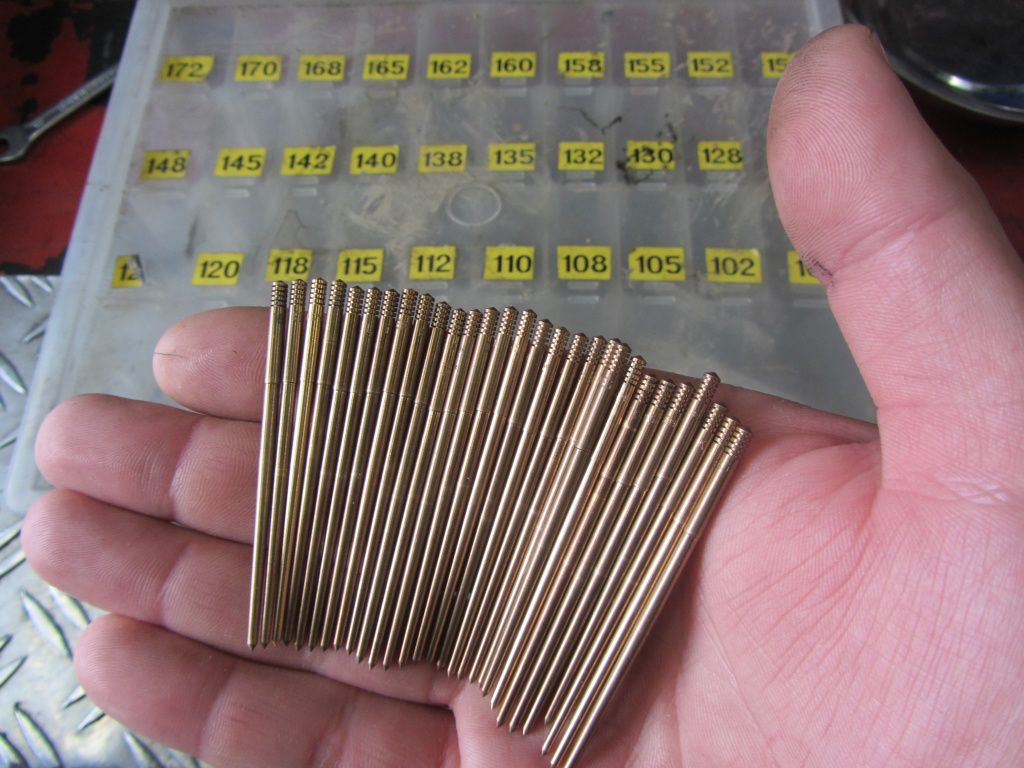

- Carburettor Dellorto PHBH 30

- Intake manifold: MBD with 6-flap reed valve (7672617KT)

- Clutch: bgm PRO 6-plate clutch (BGM8011NR46)

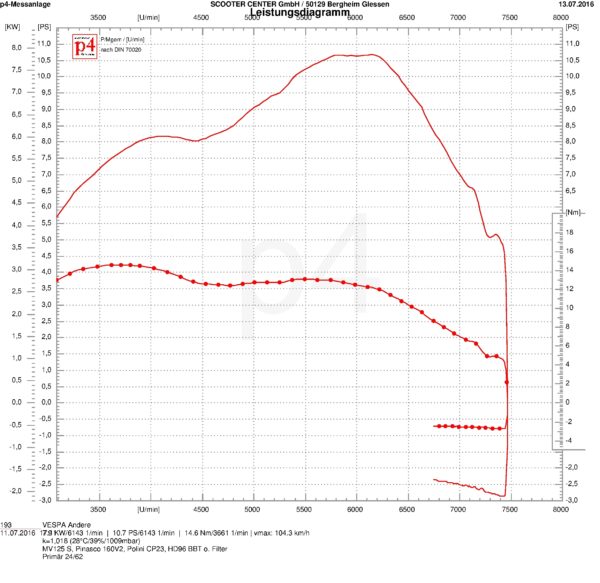

Results & conclusion of the test

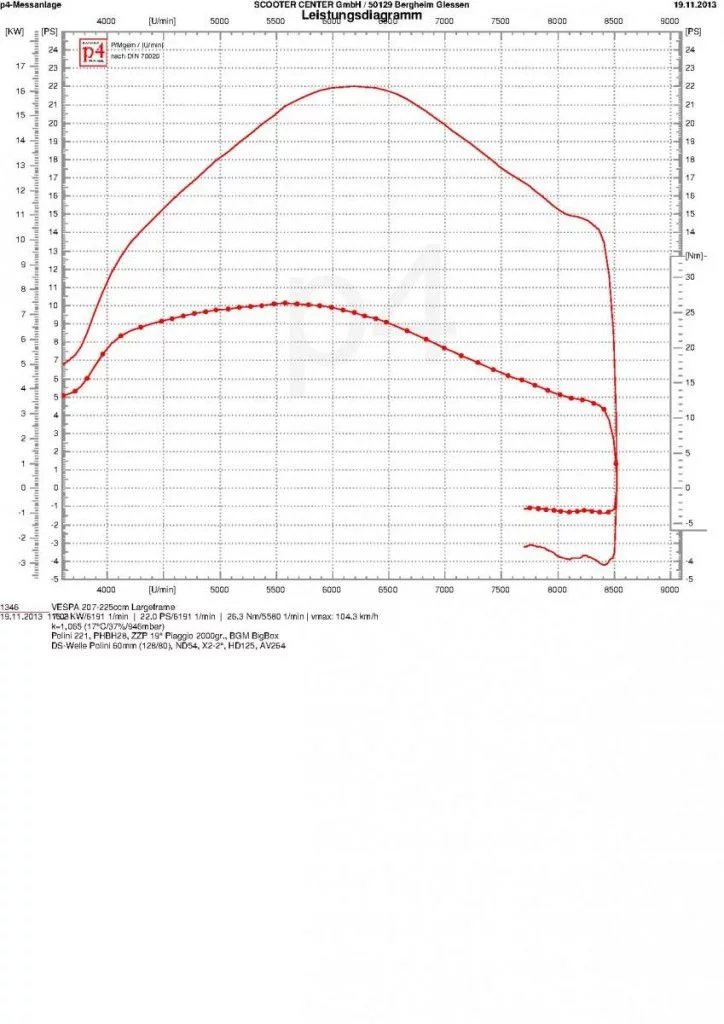

Nice and clear to see how well the box scores right from the start not only with power but also with plenty of torque compared to the ‚racing exhausts‘.

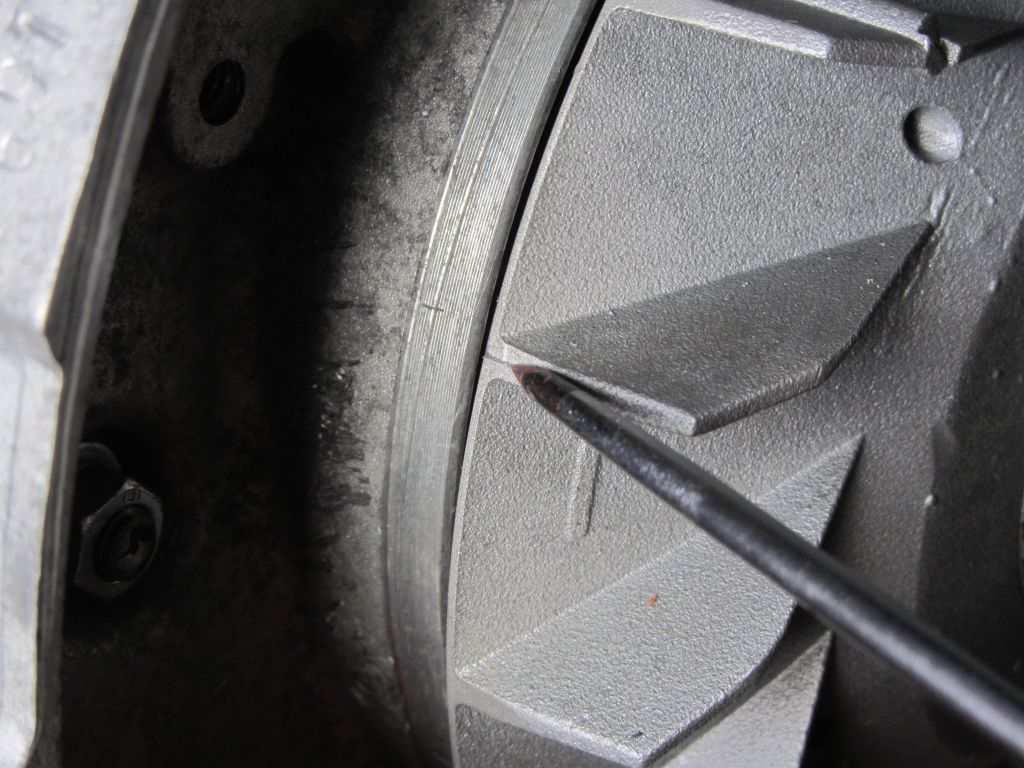

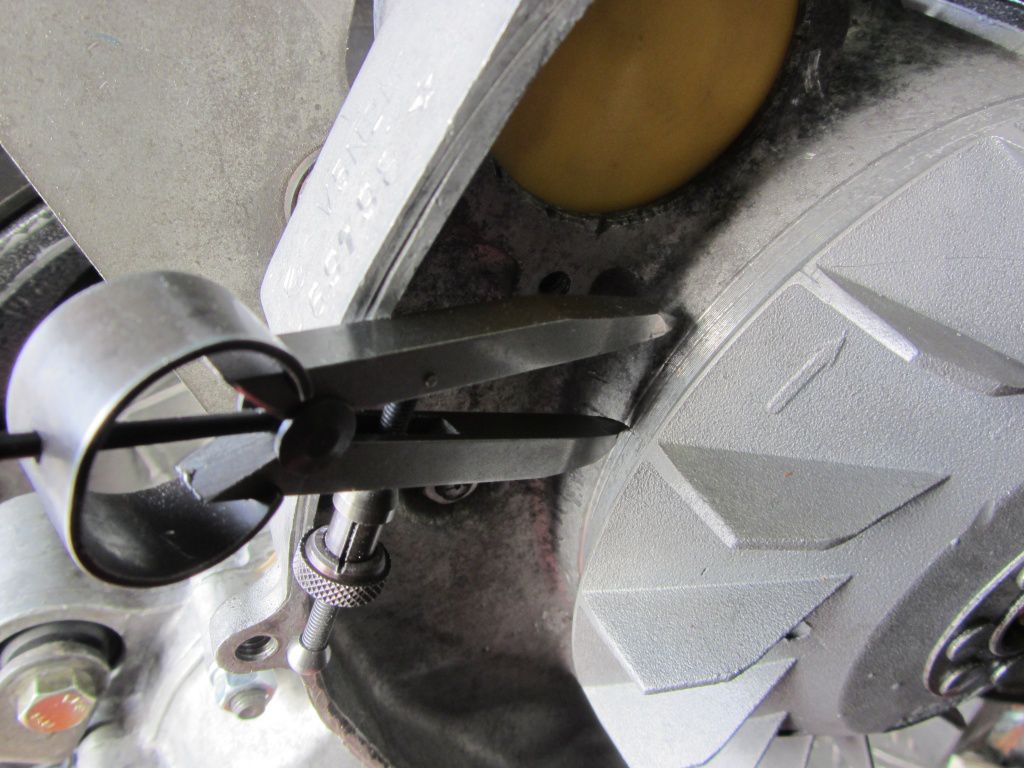

That’s what makes the bgm PRO boxes so nice to drive. There is always enough power available without having to struggle with gear connection problems or having to twist the throttle like crazy to get things moving. The moderate consumption values of the engine concepts with the bgm boxes are another advantage, apart from the original appearance and pleasant sound level. Another outstanding feature is the registered-design of the mounting system with adjustment options in both horizontal and vertical directions. This allows tolerances and, above all, spacers used for different strokes and connecting rod lengths to be compensated for.

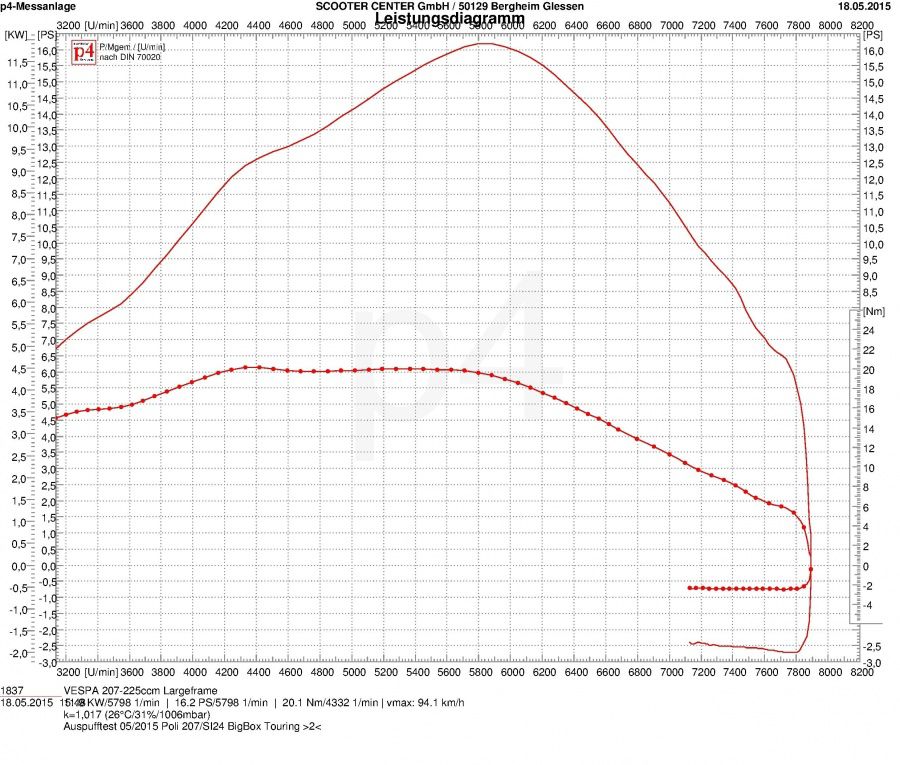

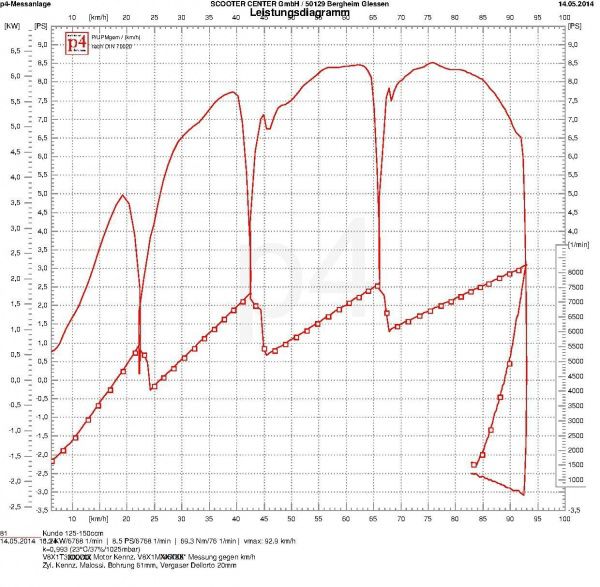

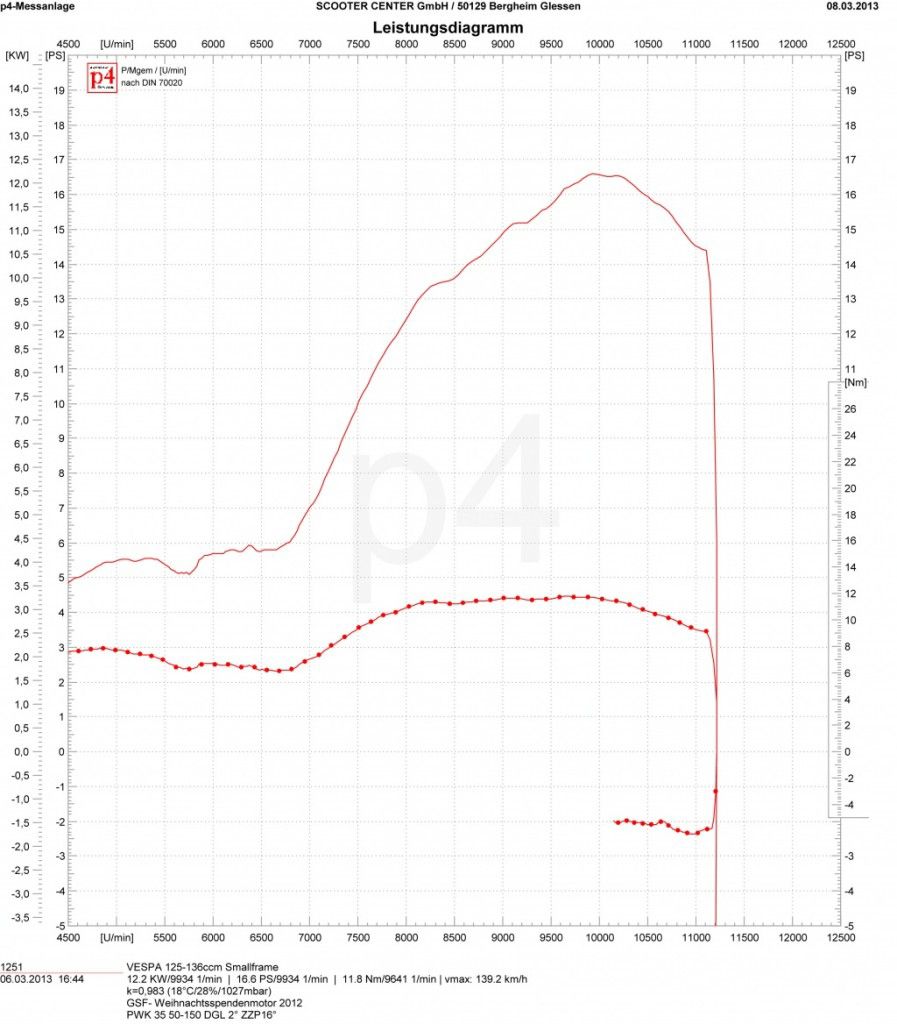

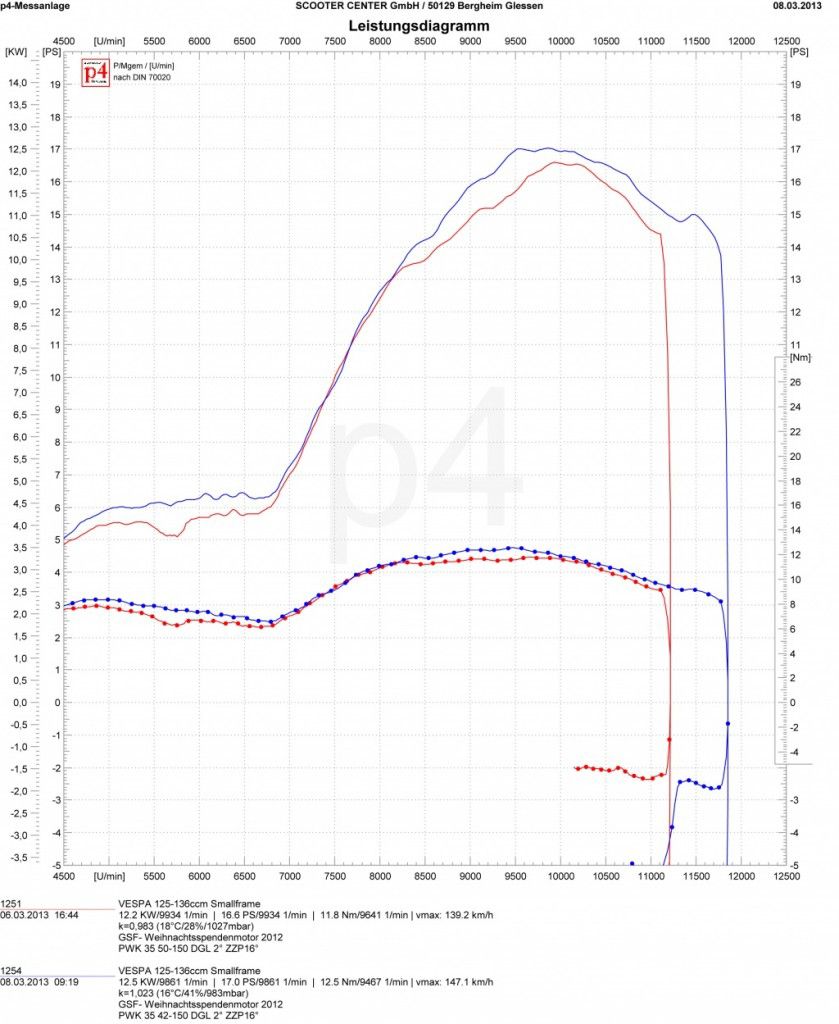

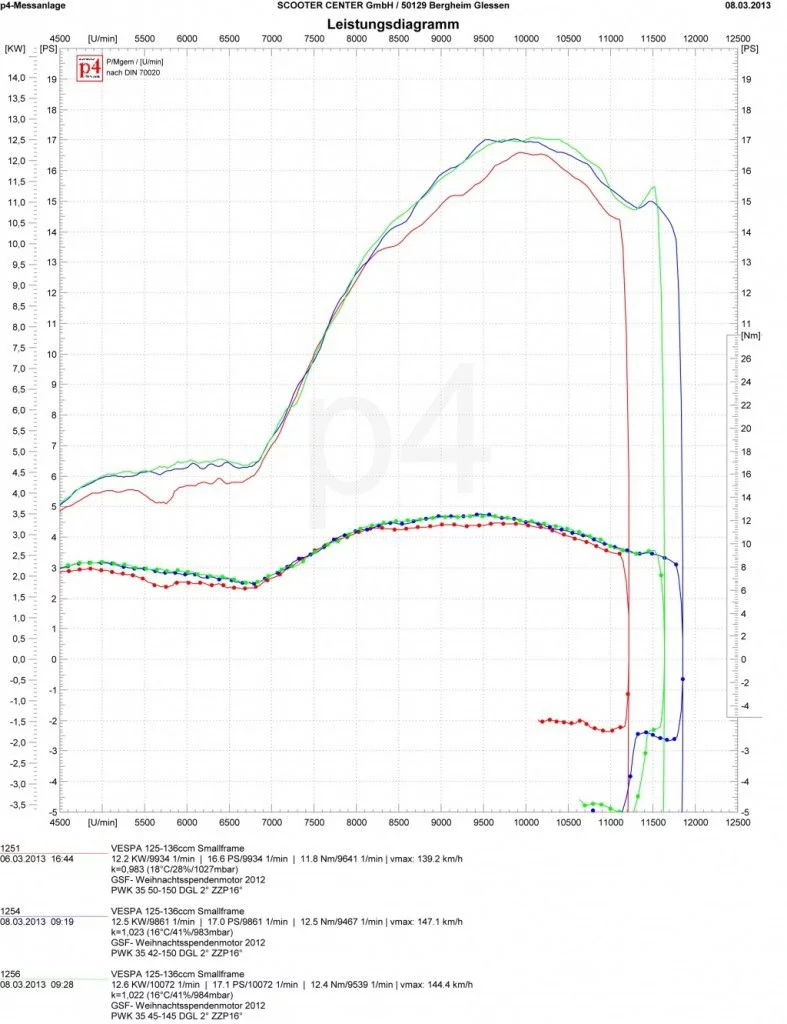

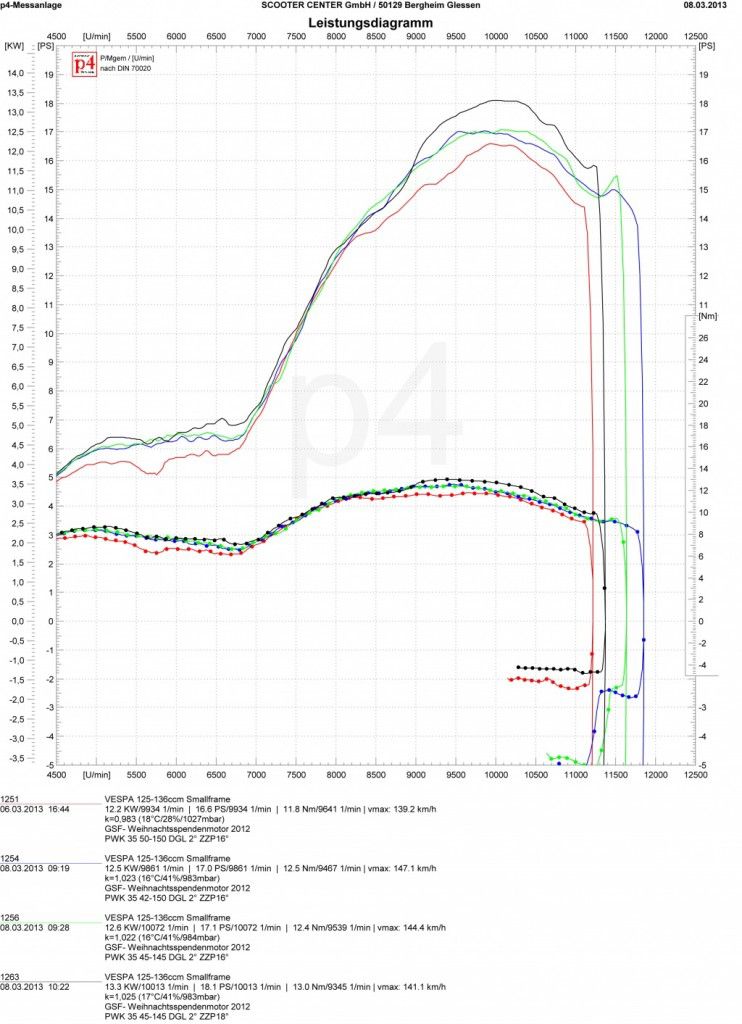

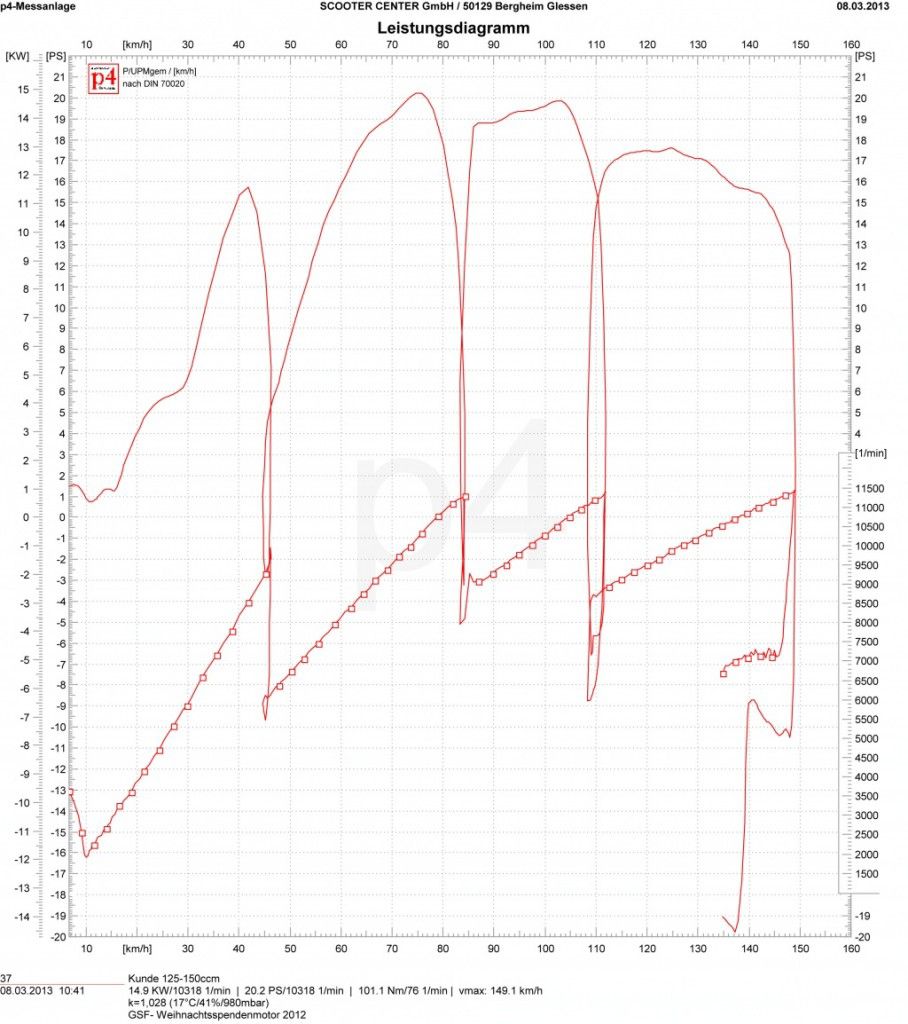

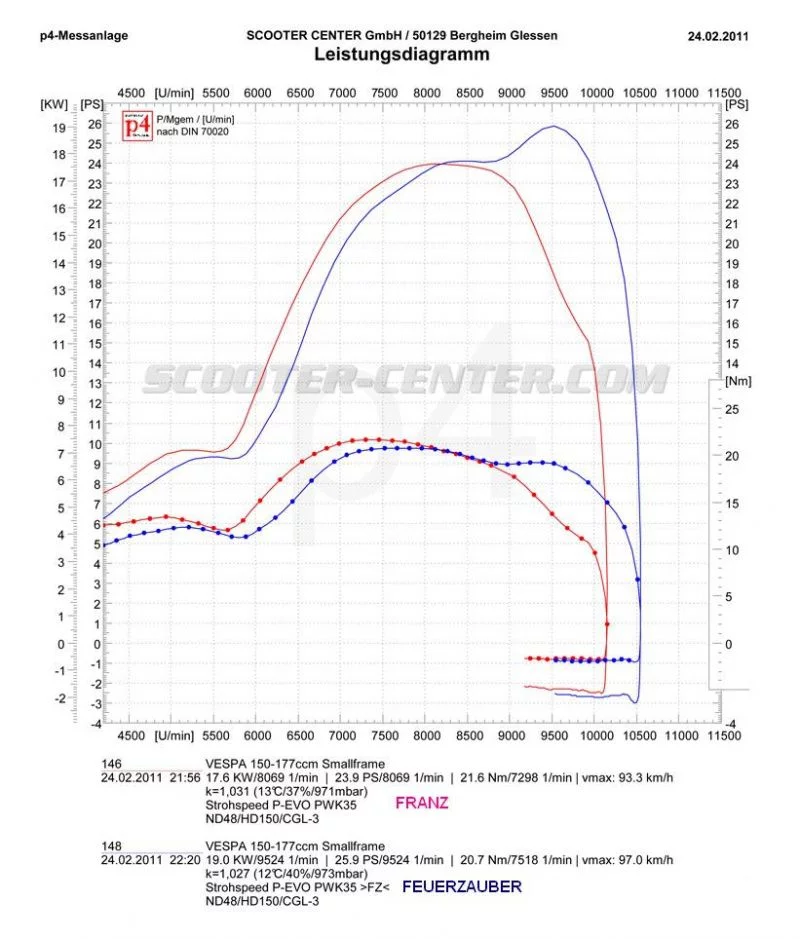

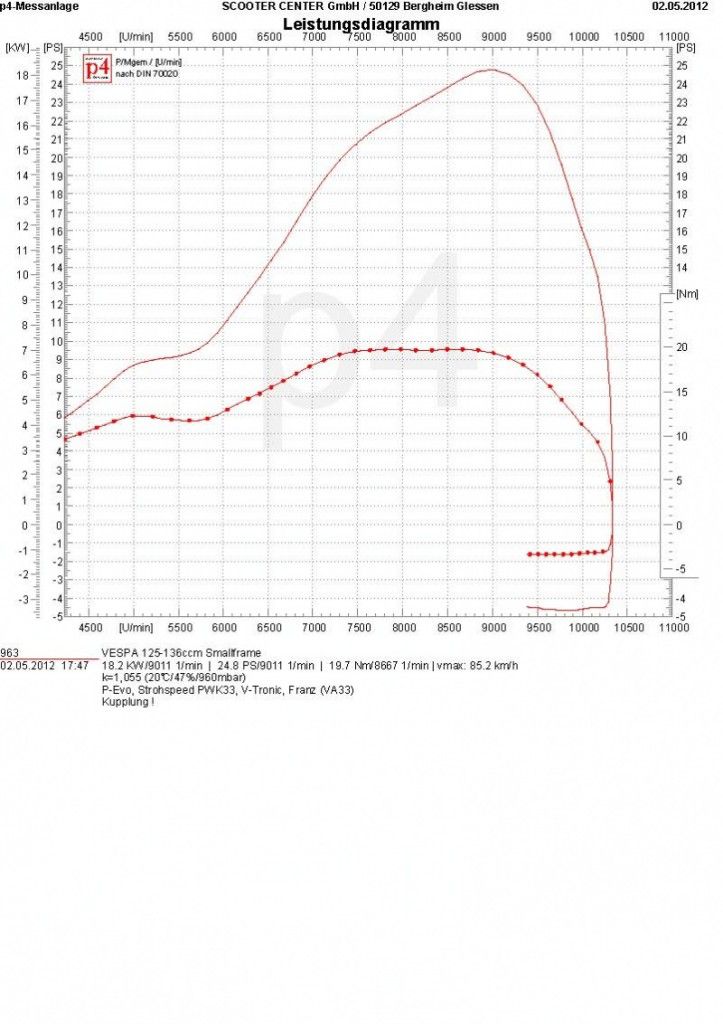

Lambretta exhaust test performance diagrams

Here you can find the performance diagrams as PDF: