As mentioned earlierPolini is going to release the alloy barrelfor the 200cc casings for long stroked engines later next year. The Polini 210cc alloy kit can be used with a 60mm stroke crankshaft, but you are limited in doing so because of different reasons. The kit contains a oiston with the top ring in L-shape. This type of piston rings runs to the top of the piston.

If you are going to use a longer stroked crankshaft e.g. 60mm instead of 57mm the 3mm longer stroke needs to be equaled in one way or another…

With the piston running 1.5mm in each direction (top and bottom dead centre) the barrel needs to be 1.5mm longer. Normally this is equaled by a base or head gasket.

With a two stroke engines power determined by the port timings, this can cause headaches or been seen as the perfect way to get the tune on barrels sorted to one’s needs. With the port timings as a trigonometric function the transfer timings are altered above average. The timings of the transfers and exhaust should always be in a certain level to work properly.

With the Polini as it comes you can use a base gasket only to equal the stroke. With a head gasket the L-type piston ring could cause trouble by running at least partially out of the bore. Is a base gasket used the port timings are raised about average and the blow down timing is affected heavily. Limiting the power up the rev range.

To achieve the good and torquey power output that the new Polini kit has out of the box, a head gasket is recommended to for te right timings. But there is the L-ring prob…

Facts…

Out of the box the new Polini has port timings of 123° transfers to 171°exhaust timing with the 57mm crankshaft. One of the best kits out of the box for touring and good power low down.

If you are going to fit the kit with a 60mm crankshaft and simply use a 1.5mm base gasket the port timings are changed to around 135°/179°.

If you are looking at the bow down timing only it is changed from 24° to 22° only. If you look at the 22° this would be still okay for a broad power curve. But if you have a look at the changes of te port timings the 135° transfer timings is far away for a road going engine. This crap design can be used with an exhaust based on the original design to make it work. So a Sito Plus or SIP Road would be the ones to go for.

230cc???

One of our customers (Thomas aka schoeni230) had a full go on the Polini alloy barrel subject. He is using it with a custom made 62.5mm crankshaft.

With a special piston instead of the standard Polini L-ring item the problem with the L-ring running out of the bore is cured.

This piston makes it possible to have the piston running out of the bore to a cretain degree:

This way a 0.4mm base gasket was sufficient to get everything right. Even with the longer stroke of 5.5mm the port timings were nearly in a reasonable area.

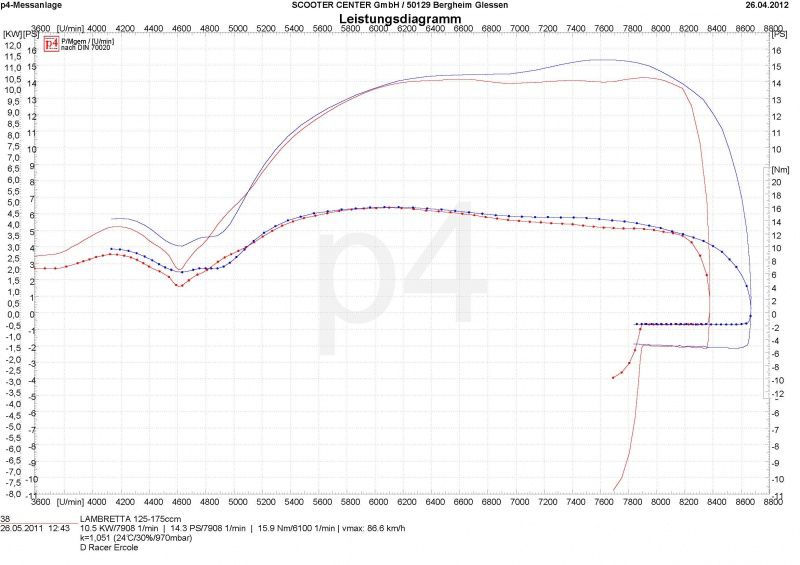

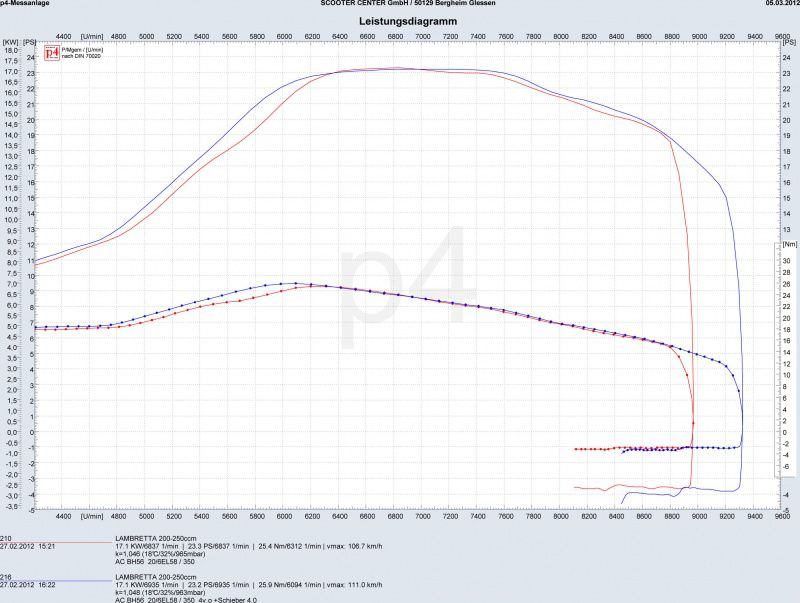

With ~133°/179° and a special cylinder head to cover the longer stroke the engines runs pretty well with a exhaust based on the PEP Big Bore design. The high torque and a really broad power band makes it a really good Rally going engine with hight top speed under every circumstance. And the top power output is -with the design of the exhaust in mind- stunning as well.

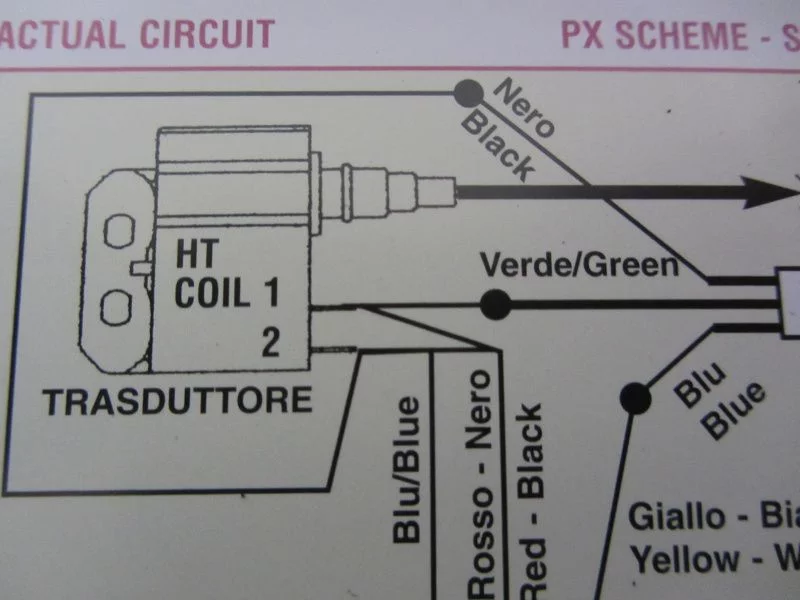

The carb used is a 35mm Keihin PWK with a Scooter & Service Reed Manifold (with V-Force Reeds). The ignition is one of the Vespatronic ones.

The barrel is nearly untouched. The exhaust port was altered only. The width and height were slightly enlarged.

UPSHOT:

Even with the port timings on the strange side, the engine should be best of all worlds and really catches one’s demands for a strong road going engine. With more than 20hp beyond the 9k rev mark.

One weak point for sure is the piston running out of the bore. Giving alignment issues of head to bore and the thermal thing at the sides of the piston are an issue as well.

The upcoming Polini for the 60mm crankshaft should be a massive step to built one of these dream engines without the need to cut so much corners.

If you are fancy this NOW, contact us. We are happy to give you advice how to built a similar engine with the 60mm crankshaft.