We had a closer look at the new Malossi Sport and MHR cylinder kits earlier. Now we check the new Polini 221 cc cylinder kit that is supossed to be used with 60 mm stroke crankshafts.

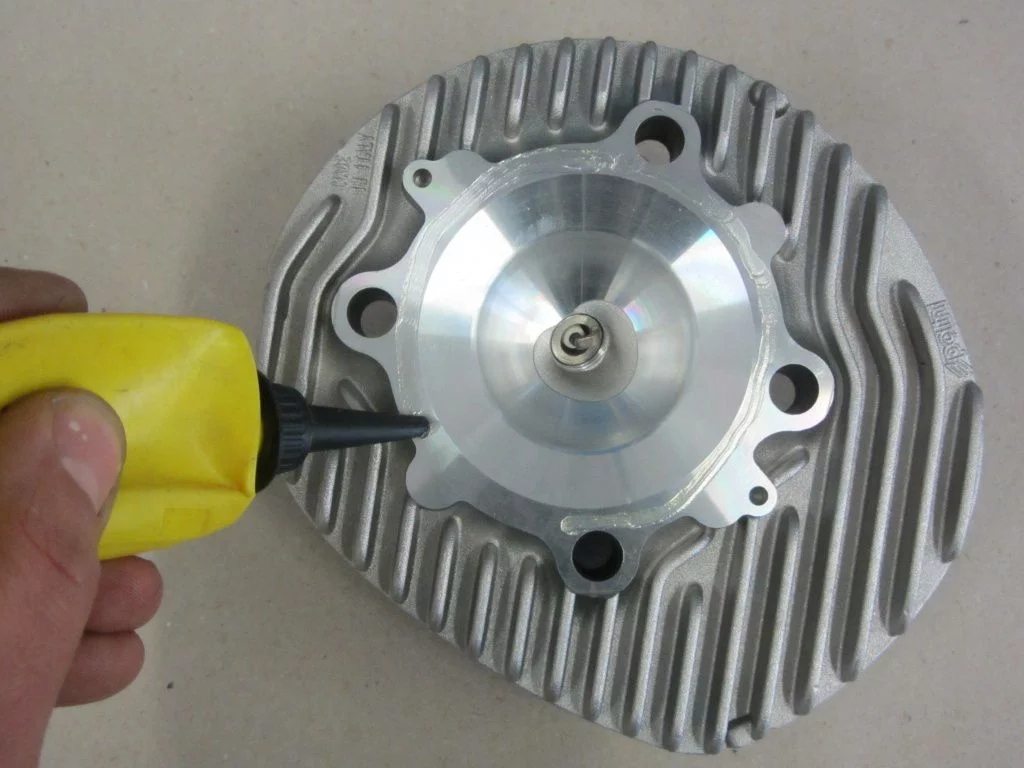

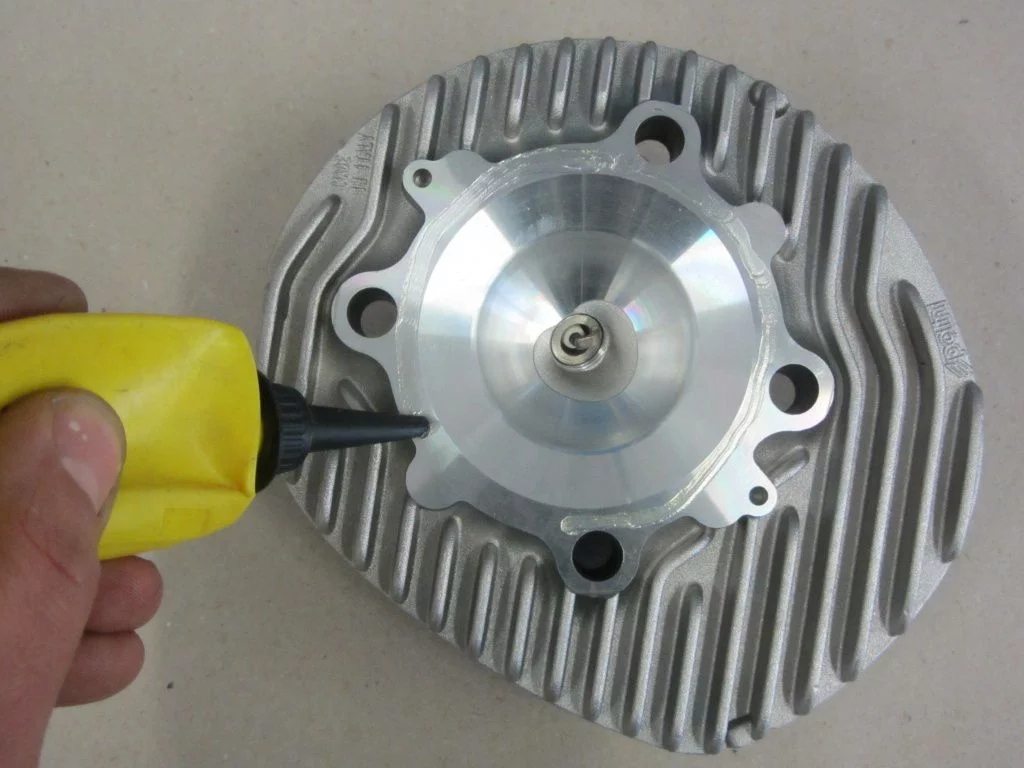

The cylinder head ist the one that is used on the Polini 210 cc as well. So let us have a look at the compression ratio of the head that is used with both kits.

Once the long threaded spark is fitted the head is tight enough for it’s closer inspection. To have our Plexiglas high tech measurement equioment sealed properly too with put a little bit grease on the head’s gasket surface.

With Plexiglas plate attached we fill up the combustion chamber with oil to get the volume of the combustion chamber.

With 25 ml putted into it, we have a 25 cc combustion chamber volume.

To get the complete combustion chamber volume (Vc) we need the volume of the curved piston dome. With a freely selected recess of the piston we can calculate the volume above the piston. We have the piston recessed by 6 mm here.

6.85 x 6.85 x 0.785 x 0.6 = 22.1 cc is the Volume of this area.

Sealed with grease and filled up with a light oil we see 14.6 ml (= 14.6 cc). So we have 22.1-14.6=7.5 cc for the volume of the piston dome.

To get the show complete we know need to have a look at the squis area volume. This needs to be measured at the engine with the parts like crank, barrel, piston and head mounted. We measure a 2.2 mm squish clearance. This gives a volume of 8.1 cc.

So we have a combustion chamber volume of:

Cylinder head 25 cc

+Squish clearance 8,1cc

-piston dome 7,5cc

=25,6cc

This gives a compression ratio ? of

Cylinder 221 cc + combustion chamber area 25,6 cc / combustion chamber volume 25,6 cc

= 246,6ccm /25,6ccm

?=9,63

So slightly higher compression ratio then the Malossi with ?=9,3 (on a 57 mm stroke engine!)

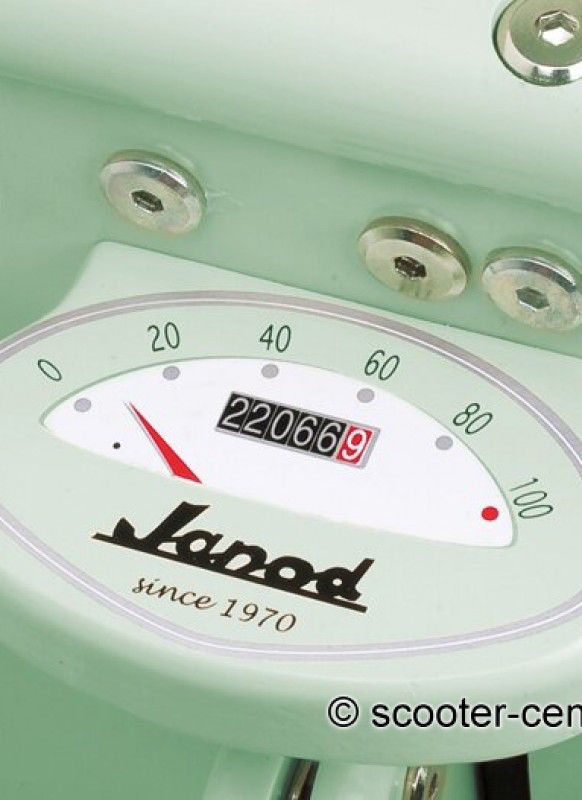

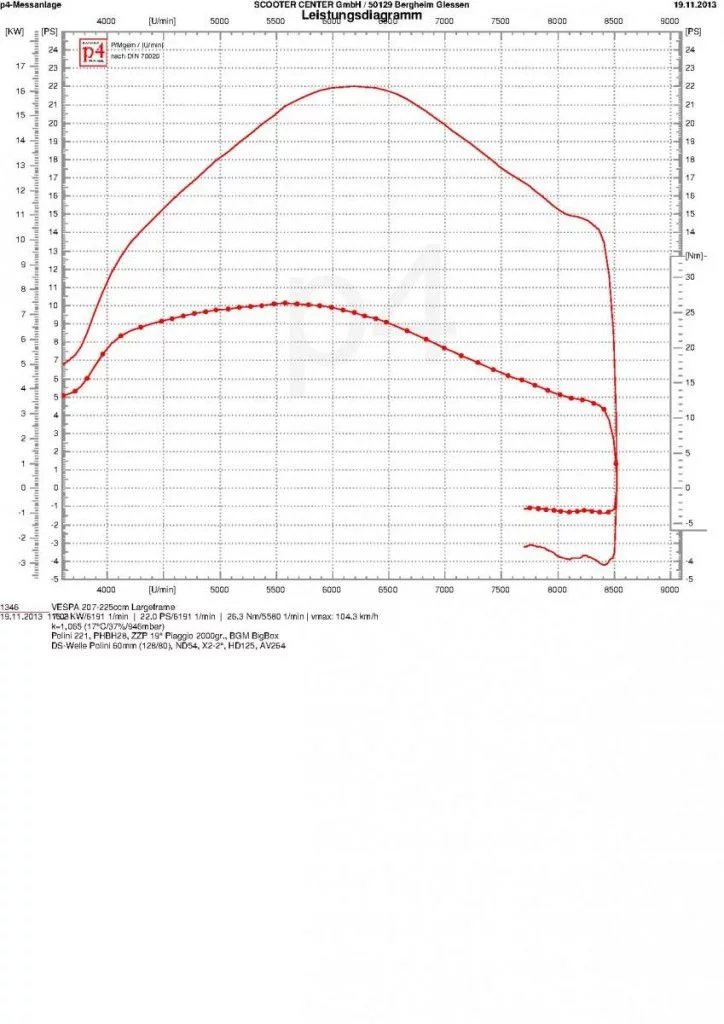

This is the Polini 221 engine of a customer.

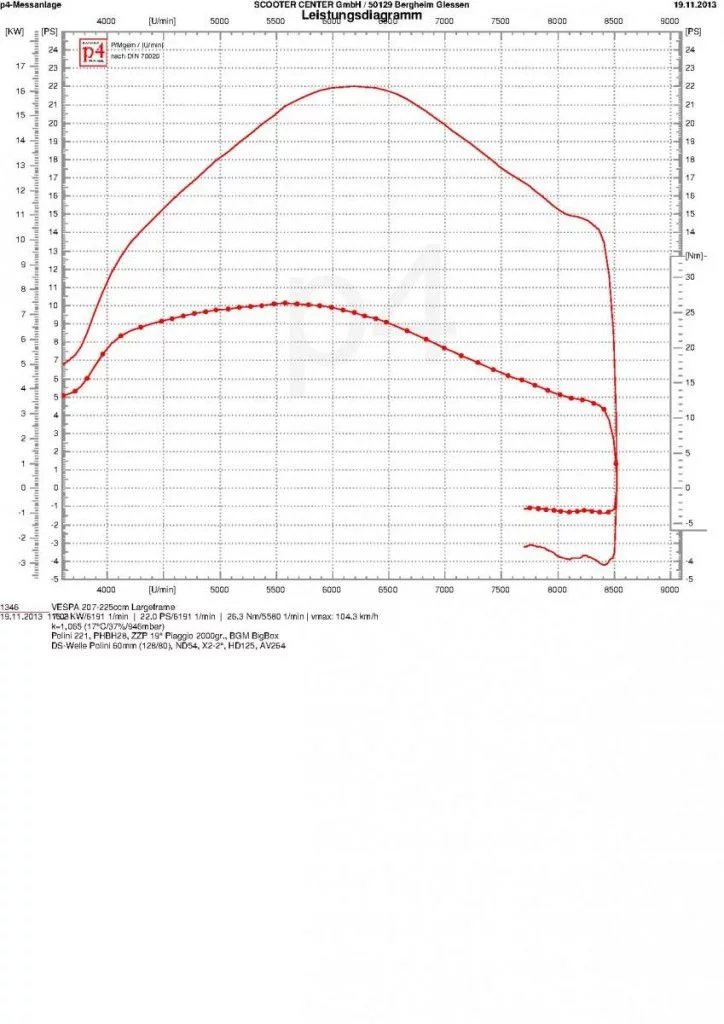

Polini 221cc, Kurbelwelle Polini 60mm stroke, Dellorto PHBH 28, Polini inlet manifold for rotary valve and with our bgm BigBox. With a standard base gasket there are port timings of 120°/170°. All details are written in the diagramm.

This is a Plug & Play engine with no further porting. And one has to admit that 26 Nm of torque are lots. Especially if they are so low down in the power band.

At 4.000 rpm we have 20 Nm this is double the torque a standard P2 engine has at peak.

Depending on the preferred riding style and for what the scooter should be used too, a taller gear ratio makes sense to not over-rev the engine all the time. The very well balanced and smooth running Polini crankshaft is a perfect companion for travelling as well as street racing…

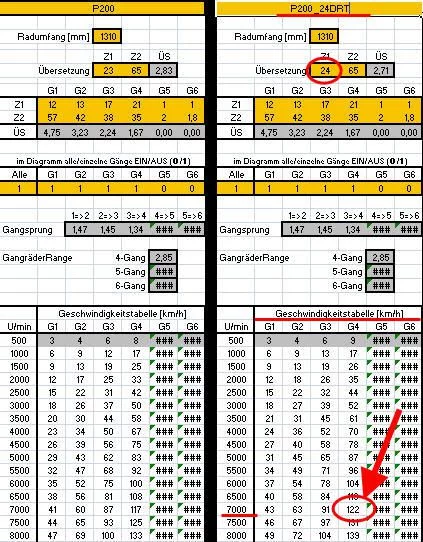

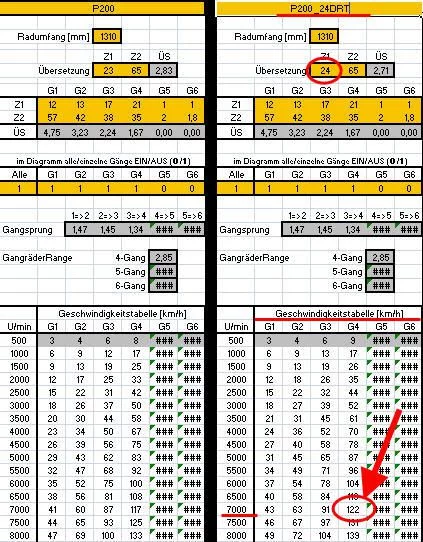

This engine setup and a longer gear ratio should give an engine that should sit for long distance travells easily at 120 km/h. Here **as an example with an original gearbox, compared to our bgm bgm Superstrong clutch with DRT sprocket with one tooth more and the original primary drive of the P2 with 65 teeth.

With 20 hp at 7.000 rpm it should be easy to do the often quoted 120 km/h mark.

** The“GearCalc“ calculator was given to use from GSF member Motorhead. Cheers!