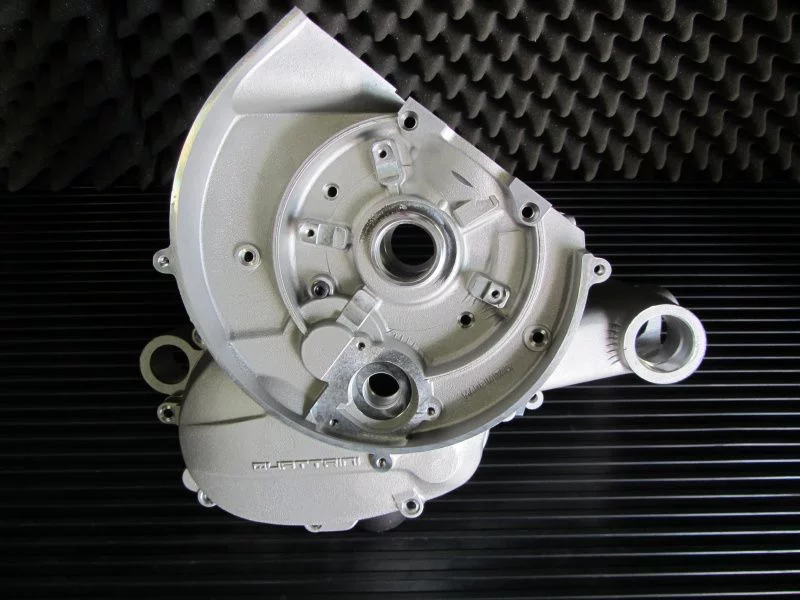

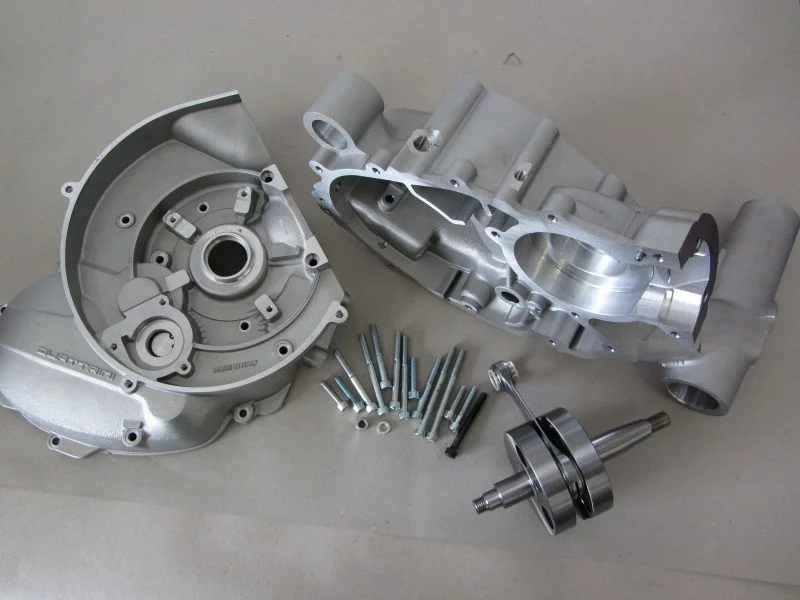

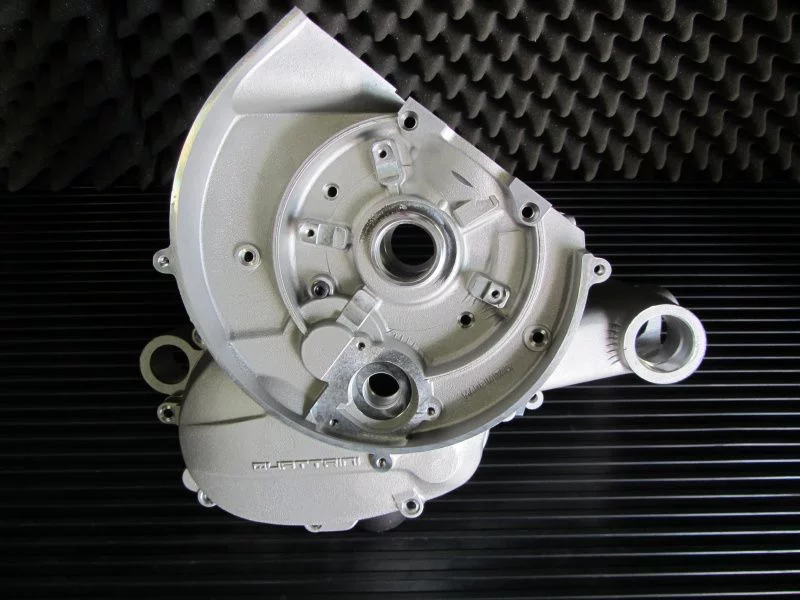

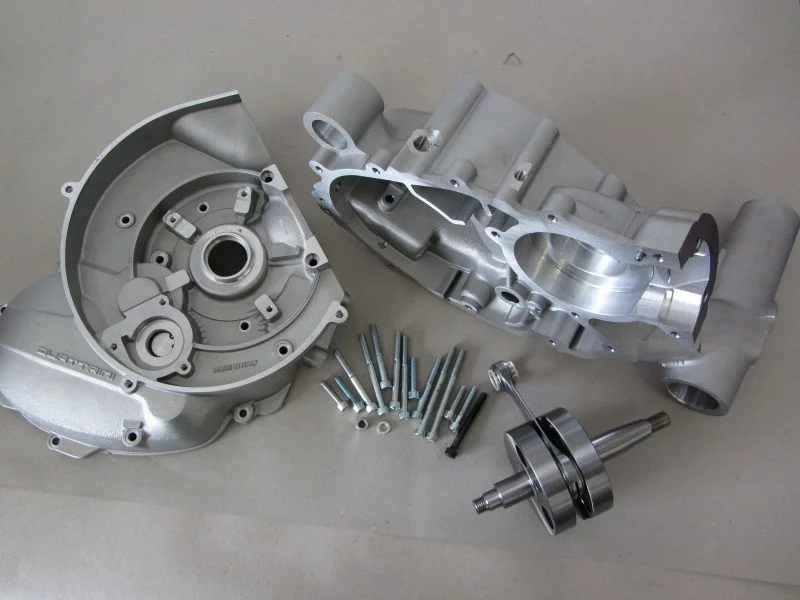

Finally the new Qattrini C1 Smallframe Engine Casings are available.

For all tuning scooterists out there a must-have.

In the past few years the Smallframe tuning become more and more versile.

Smallframe engines with more than 40hp are no longer unique nowadays. The original Piaggio engine casings were produced for power around 10hp. The power given through cylinder kits like Parmakit, Falc or Qattrini are just too much for the original casings.

Quattrini has met demands and developed a very sophisticated engine housing..

We are going to show you the new features below.

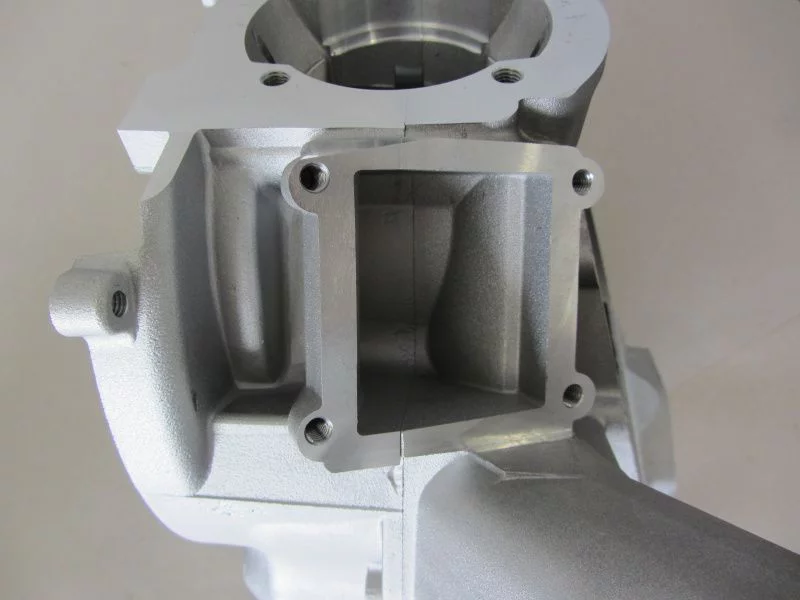

The first eye-catching feature is the adapter for a mechanical water pump to install water-cooled cylinders.

If you make use of the classical forced air cooling, Quattrini also included an aluminum plug to close the bore of the pump.

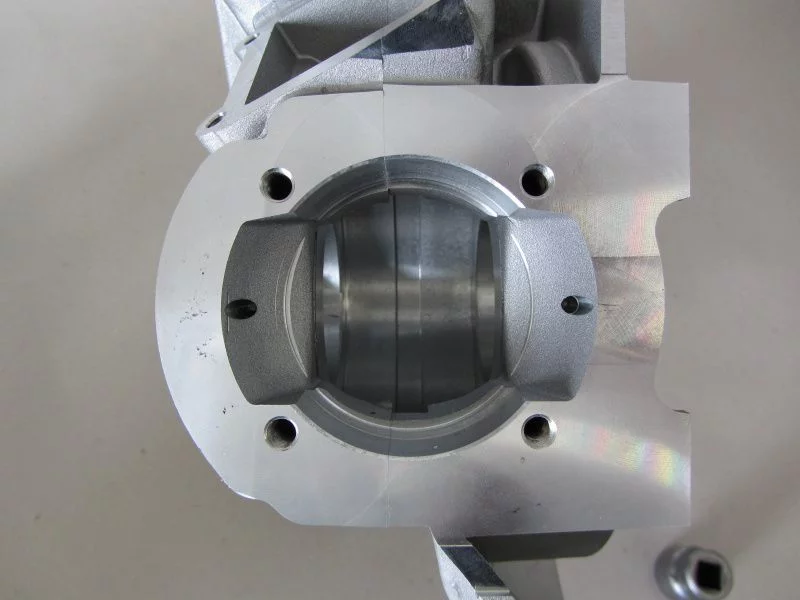

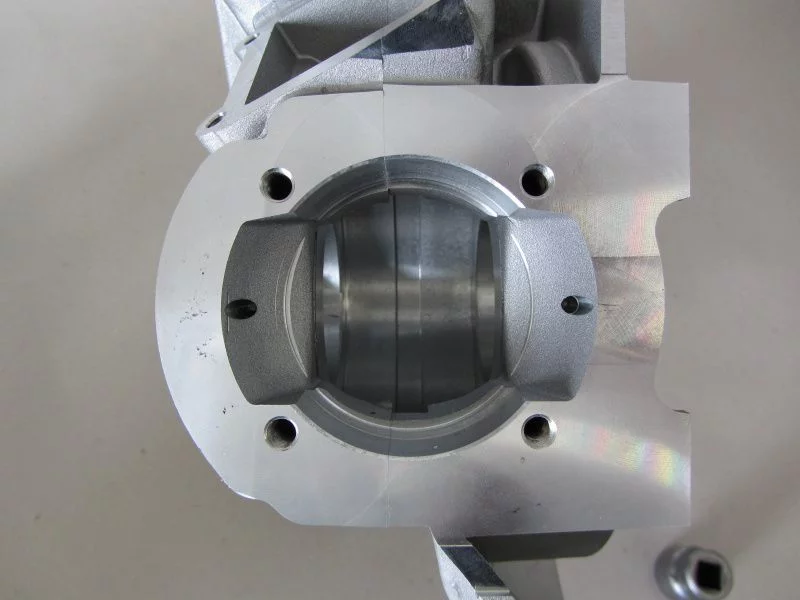

The area around the floating ports and the cylinder base is made considerably more massive in order to prevent casing failure or cracks.

Quattrini already spindled the cylinder base to 64.8 mm diameter and 17.5 mm deep.

Including a range up to 21mm deep, which is suitable for the original spindled cylinder base diameter.

The area around the engine mount is adjusted so that you can use Tyres in the dimension of 3.50×10.

To compensate the weakening of the engine mount through the heel, this was reinforced with 4 solid ribs.

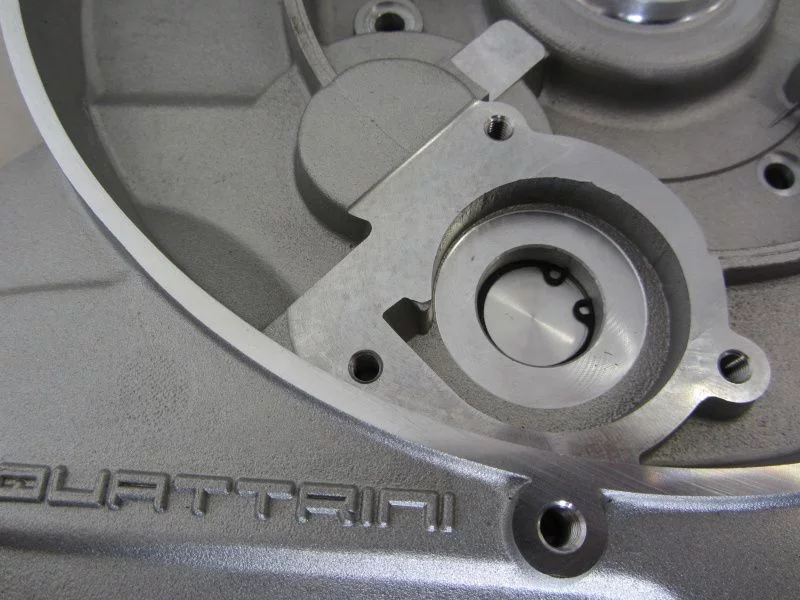

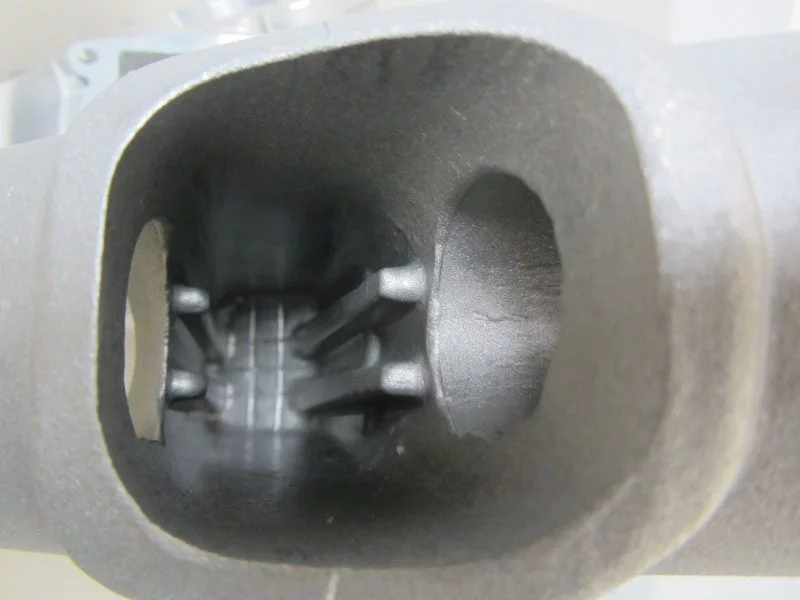

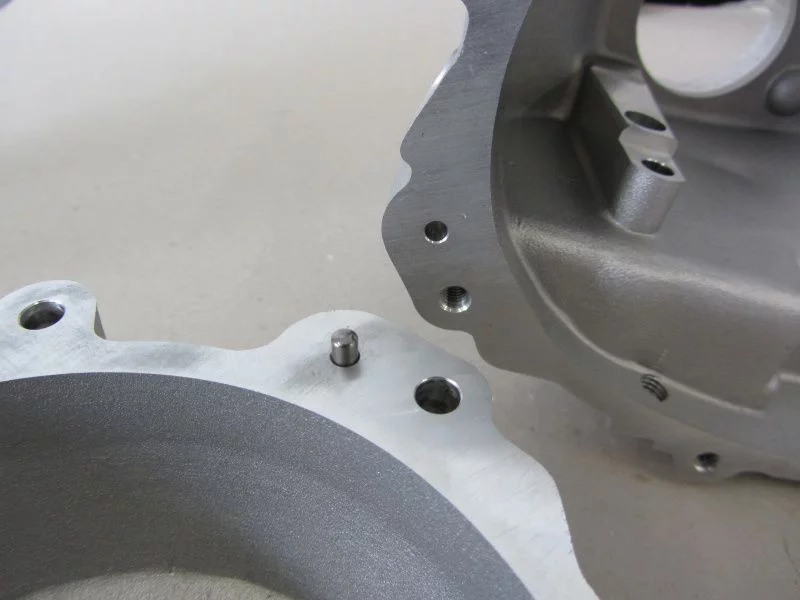

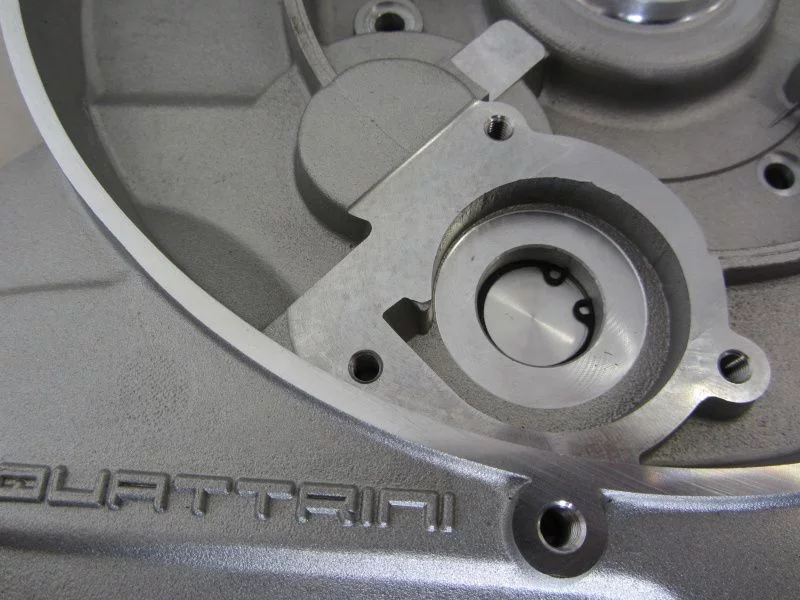

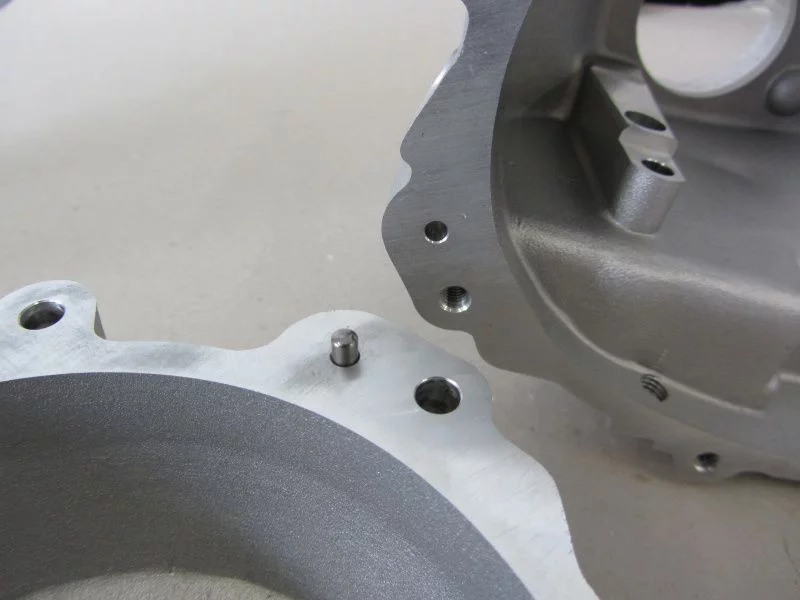

The two housing halves are connected with two centre pins and M6 screws, which will prevent the mounting with separate nuts. Because of the cast membrane and the lack of box centered on the crankcase cover gasket also eliminates the paper based engine seal. Common practice today is to use sealant in order to put the engine together sealant. We recommend from experience Dirko HT.

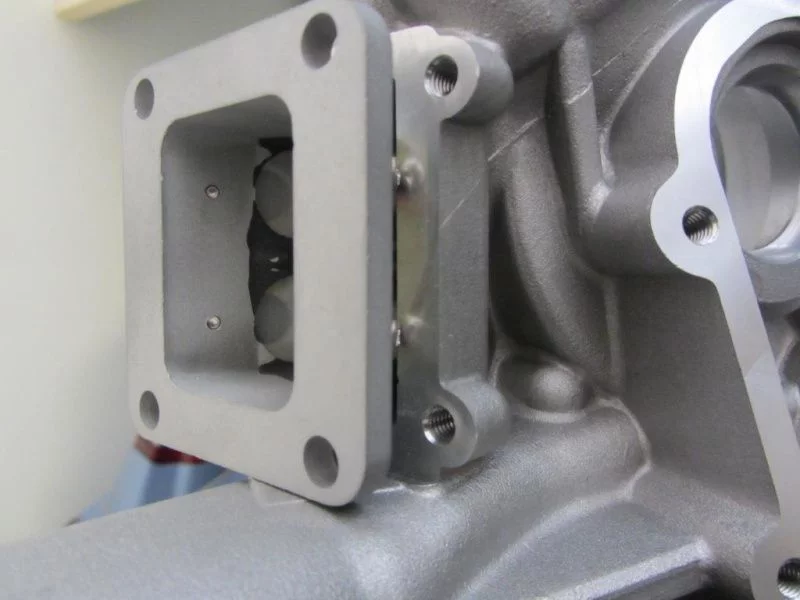

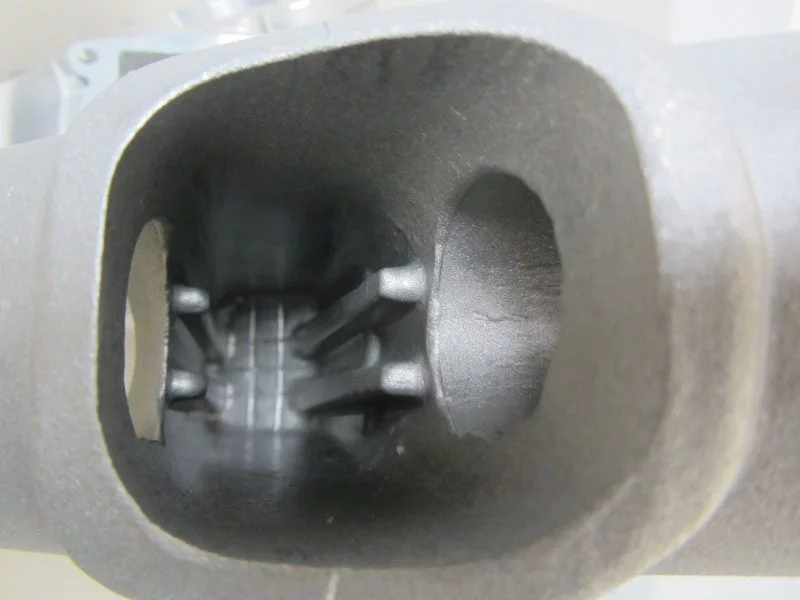

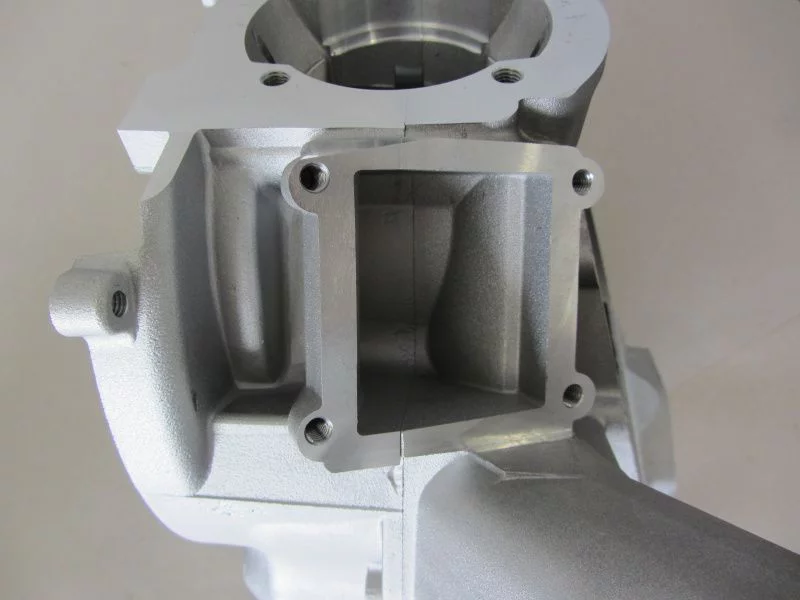

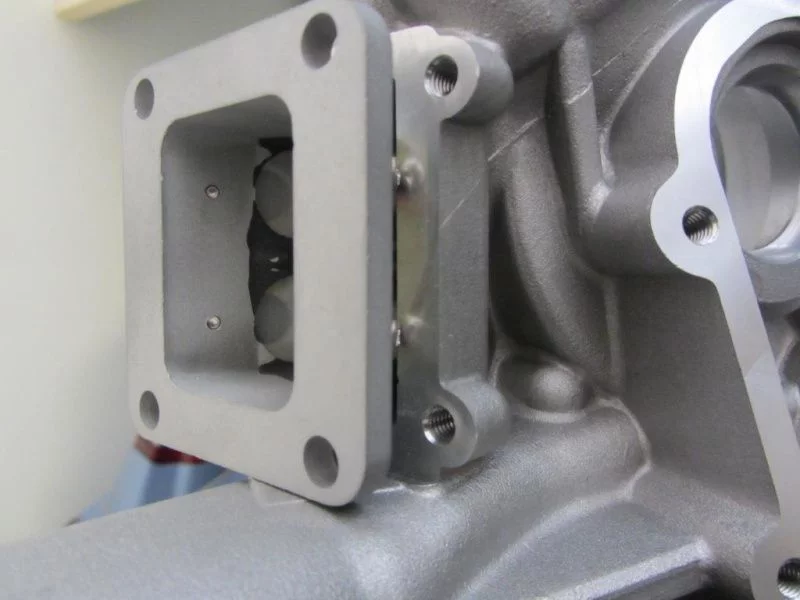

Condition as supplied to customers the casings are ready to use with direct intake cylinders. Additionally Quattrini also designed a box for all friends of membrane intake.

The connection to the crankcase must be machined if required, however, on its own power out.

Unfortunately, until now it is not absolutely clear which membrane can be used.

Therefore, we have already taken care of a solution and started to adjust aRD350 and V-Force³ Membrane.

Regarding the gear shift Quattrini stayed with the good old 2 cable technique.

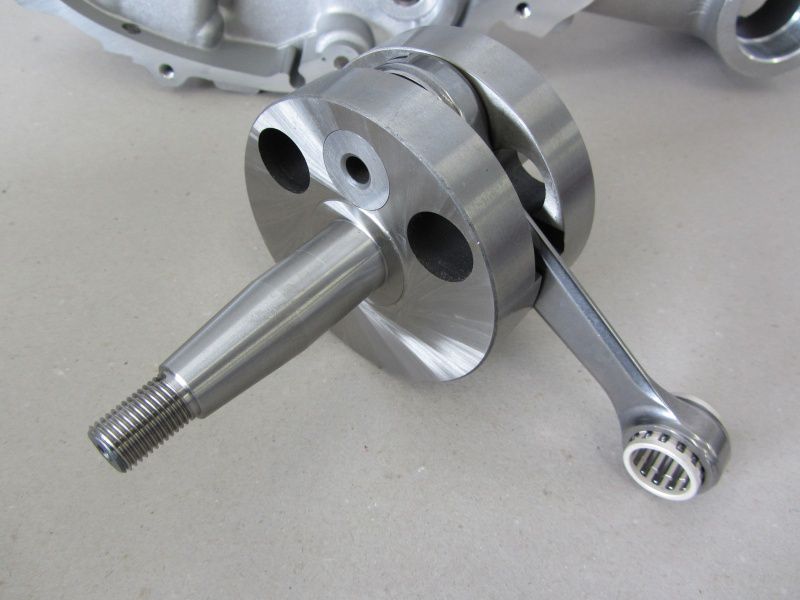

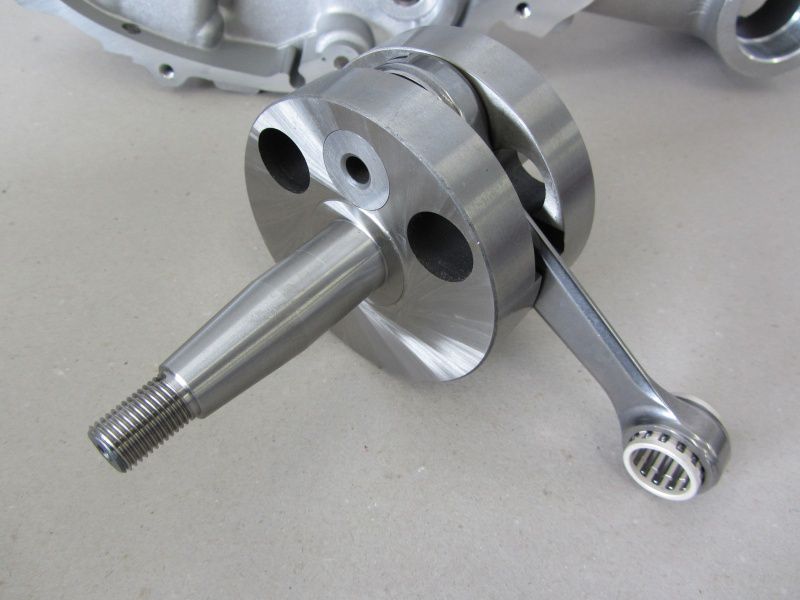

The heart of the whole new design is based on the 48mm broadend crank shaft with 51mm rod.

This measure ensures that the press dimension of crank pin increases significantly

and the crankshaft is turning resistance in terms of not to being twisted.

The high quality 102mm conrod round off the overall good impression. The dimension of the center crankshaft bearing and cylinder base sealing is 69mm and is thus provided for the use of 102mm connecting rod.

As crankshaft bearings we are using 6304TN9C4 on both sides.

It is also conceivable to mount a NU205 on the generator side, but we do not recommend it.

The crankcase is additionally sealed with 2 oil seals from both sides with the dimensions 20x35x7. Here we can offer youseals in good old FPM-Quality.

Depending on the ignition used for this engine, a whole for the cable set must be made in the dynamo casing.

The air channel has been changed already for the use of Race Exhaust.

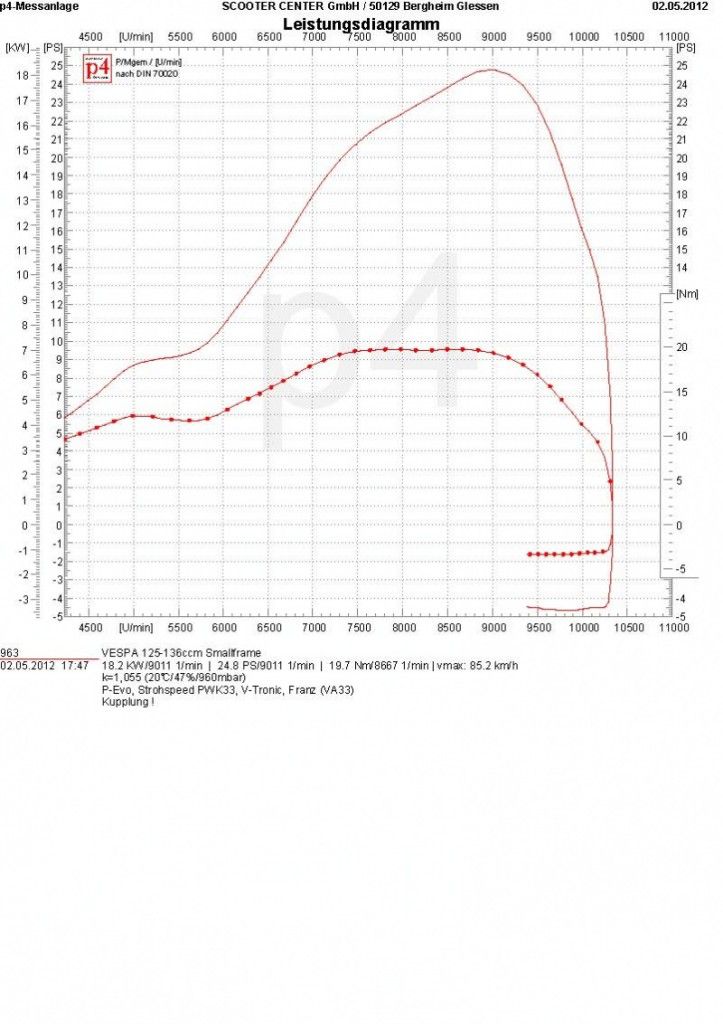

After the spectacular performance of the Quattrini engine casings at the start of the ESC season in Mirecourt, we are curious to see who is using them first.