Transfer ports mill engine Vespa PX

The Vespa engine – the heart of Platónika – has received the desired control angles of the crankshaft in the last article

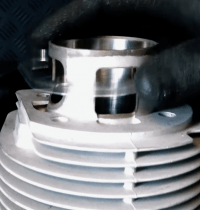

Cylinder transfer ports in the engine adapt for performance optimization

Before the complete assembly of the motor can be done, all work that generates chips must be done. Only then can the housing be cleaned.

In the next step, this includes the ports of the cylinder in the engine.

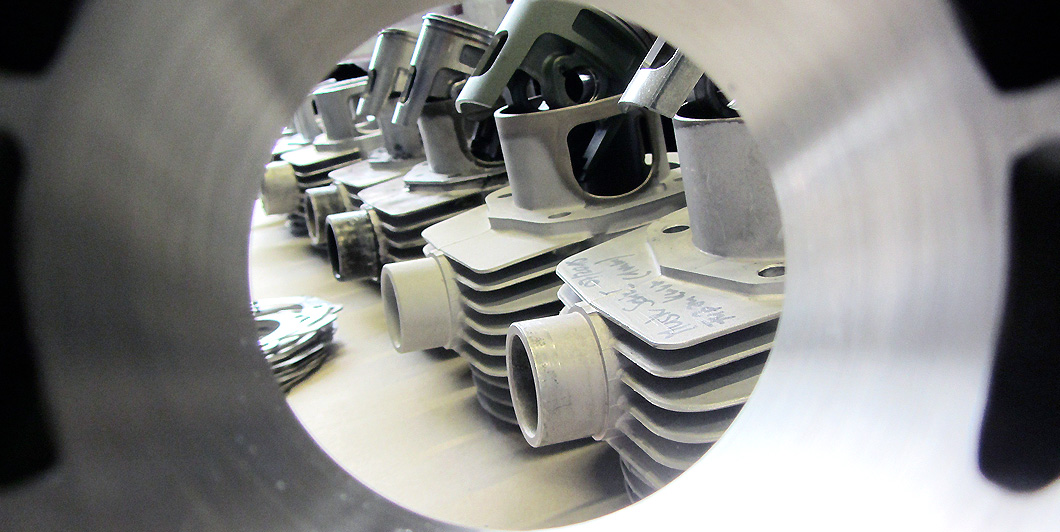

The BGM177 is designed in such a way that the cylinder functions perfectly even on the original ports.

However, in our project we took the opportunity to directly adapt the case. A better filling of the cylinder always means a higher possible torque.

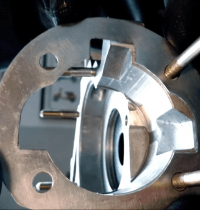

In order to transfer the contour of the overcurrent channels to the motor housing, the easiest way is to place the matching cylinder base gasket on the housing and thus transfer the contour to the housing.

The sealing surface is best marked with a foil pen. Then the contour of the overflow channels is marked with the aid of the cylinder base gasket.

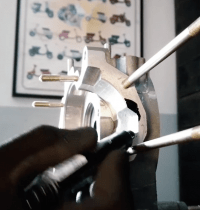

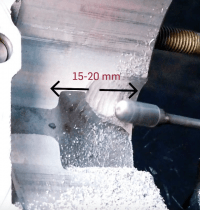

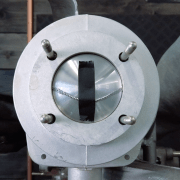

A milling cutter is then used to adapt the contour in the motor housing. It is not necessary to mill the channel exactly as deep as in the original motor housing.

The BGM 177 cylinder is designed from the basic construction so that the piston offers a sufficient cross section.

The generated surface of the adapted channel may be milled rough. Further polishing is not necessary. As long as there are no more rough corners and edges, a slightly roughened surface is perfect.

After the channels have been milled and the housing has been cleaned again, the assembly process continues