Vespa PX LED Headlight

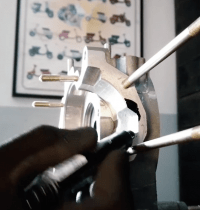

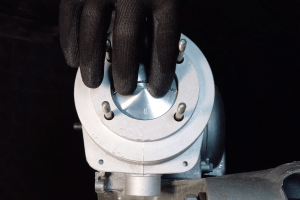

In this Vespa tutorial video we show you how to install our Vespa PX LED headlight for the Vespa PX. The MOTO NOSTRA HighPower LED headlight itself can also be installed in other cars (Lambretta, Vespa GTS, Sprint, Rally). With the included car specific frame, the installation of the Vespa PX LED headlight as e.g. Vespa PX LED headlight is very easy

CONTENT

WHY AN LED HEADLIGHT ON THE VESPA?

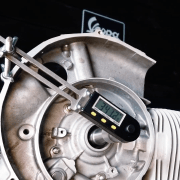

The limit with conventional Bilux bulbs is on most scooters a headlight bulb with 45/45 W. The 80 W to max. 120 W ignition does not give more. The luminosity measured in lumens is less than 400 and the LED headlight has a luminosity three times as high (1300 lumens). The power consumption is only 20 W. This corresponds to the luminous efficiency of a conventional 100 Watt spotlight. This means that with a given alternator/power supply a considerably better illumination can be achieved. In addition, more capacity remains for other consumers

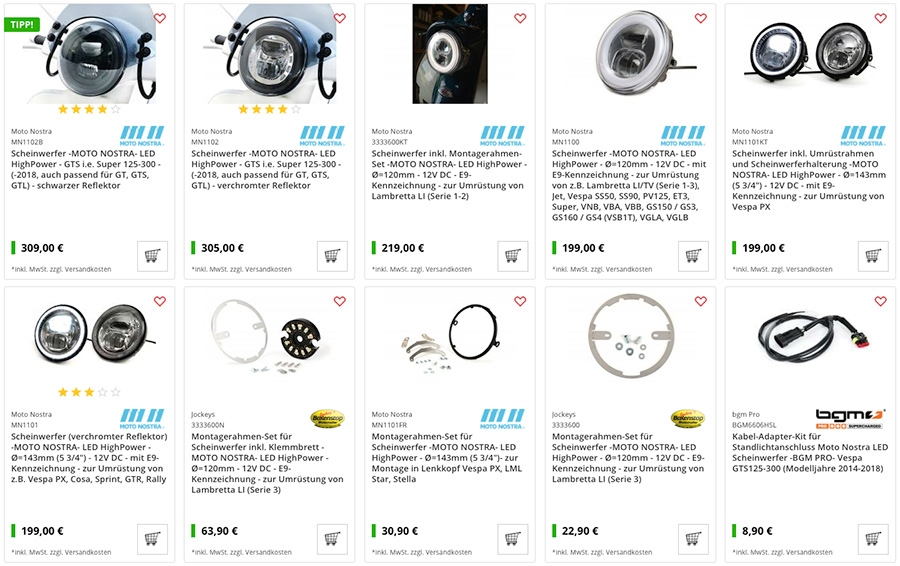

PARTS LIST / SHOP

Parts used in this video

- LED headlights incl. conversion frame Vespa PX and headlight bracket -MOTO NOSTRA- LED HighPower

Article number: mn1101kt

- Ignition switch -VESPA 4-cable- Vespa PX Lusso (from year 1984 up)

Item number: 9520133

- Light switch -GRABOR- Vespa PK125 XL/ETS, Vespa PX Elestart (1984-1998) – 10 cables (DC, models with battery, normally open)

Item number: 9520145

- Rubber flasher relay Vespa PX

Item number: 3330940

MOTO NOSTA LED HEADLIGHT!

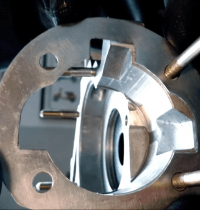

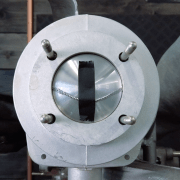

LED headlamp with E9 marking (road approval) and high-intensity main/dipped beam. Additional feature is a separately switchable position light. With a diameter of 143mm it also fits perfectly in the steering head of the PX and Cosa models as well as in the lamp bezel of e.g. Vespa Sprint, GTR and Rally.

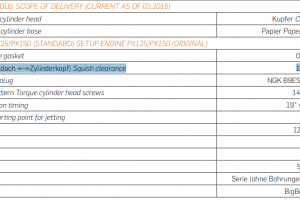

TECHNICAL DATA

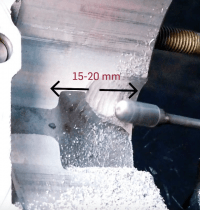

Luminosity 1300 lumen Voltage: 12 Volt DC (direct current) Power consumption: 1.8A/1.3A Power consumption: 21.5W/15W/1.9W Diameter: Ø143mm Overall depth body: 54mm (measured from headlight ring without glass bulge) Overall depth overall: 79mm (measured from headlight ring without glass bulge with cable entry)

NOTE

The LED headlight works exclusively with direct current, therefore it needs a battery or another equivalent power source with 12V DC. Operation with an AC power source will result in immediate failure