Clutch holding tool Vespa Smallframe V50, PV, ET3, PK, PK XL – Item number 7675436

Modern day cylinder kits and full expansion chambers give amazing power outputs to the Smallframe Vespa. Setups like the Polini Evo used with the Big Bertha expansion chamber like on our Generation XI, give more than 24Nm torque at the rear wheel.

To get the power from the top end to the bottom emd you have the clutch unit. With the high power outputs the clutch is under enormous stress. This connection has to be built with the needed care to get it reliable and long lasting.

Good practise these days is to grind-in the clutch on the auxiliary shaft with valve grinding paste and afterwards to tighten down the primary drive and clutch nut to 70 Nm.

Specially for these high torque settings we have clutch- and primary drive nuts in high tensile steel. These even sustain torque settings much higher htan 70 Nm. Because these are collar nuts the usually used securing washers are no longer needed. Good practice is to use screw retaining glue.

To avoid any damages to the clutch basket and primary drive while putting such high torque figu´res thru the wrench, we have a new clutch holding tool now.

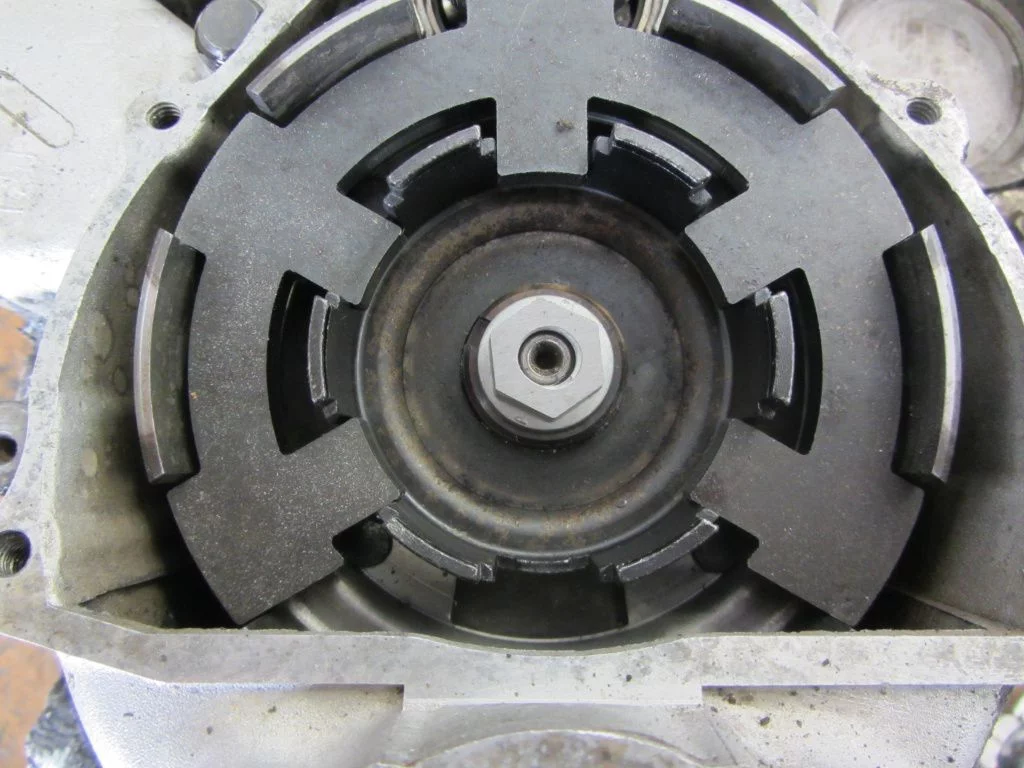

With this neat tool inner baskets of the V50/XL1 clutch

- Innenkorb V50 / PK XL1

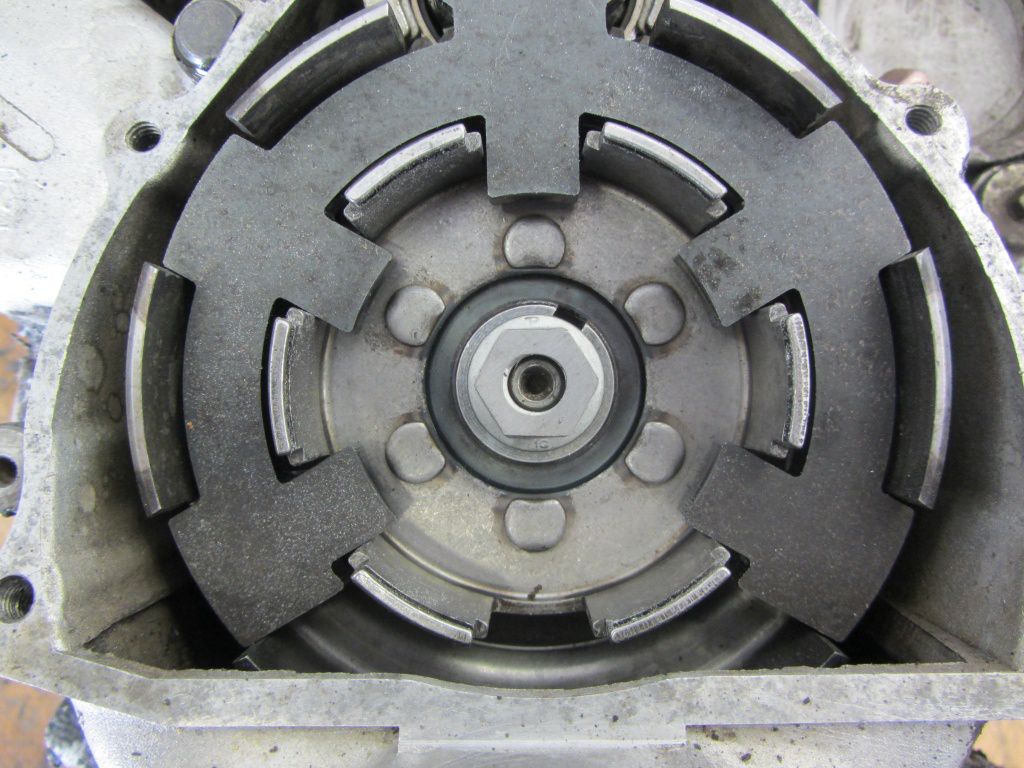

As well as clutch inner basket of the PK XL2 can be locked for tightning down the nut.

The usual blocking of the primary drive the force put into the engine components is so high that they can easily be damaged.

Our clutch holding tool can be rested against a nut on the primary drive or against a screw fitted to the thread of the engine casings.

So the high torque figures are not transmitted to the bearing seats or the cushion drive.

So the high torque figures are not transmitted to the bearing seats or the cushion drive.

With our Multitool the clutch can even be assembled while fitted in the engine.

Leave a Reply

Want to join the discussion?Feel free to contribute!