On the dyno: GSF charity engine ’20 plus horsepower’ – Pt. 2

To do the first dyno runs, we just had to fit the cables. You might remember?

The engine came at least the idel and main jet, while the needle were missing.

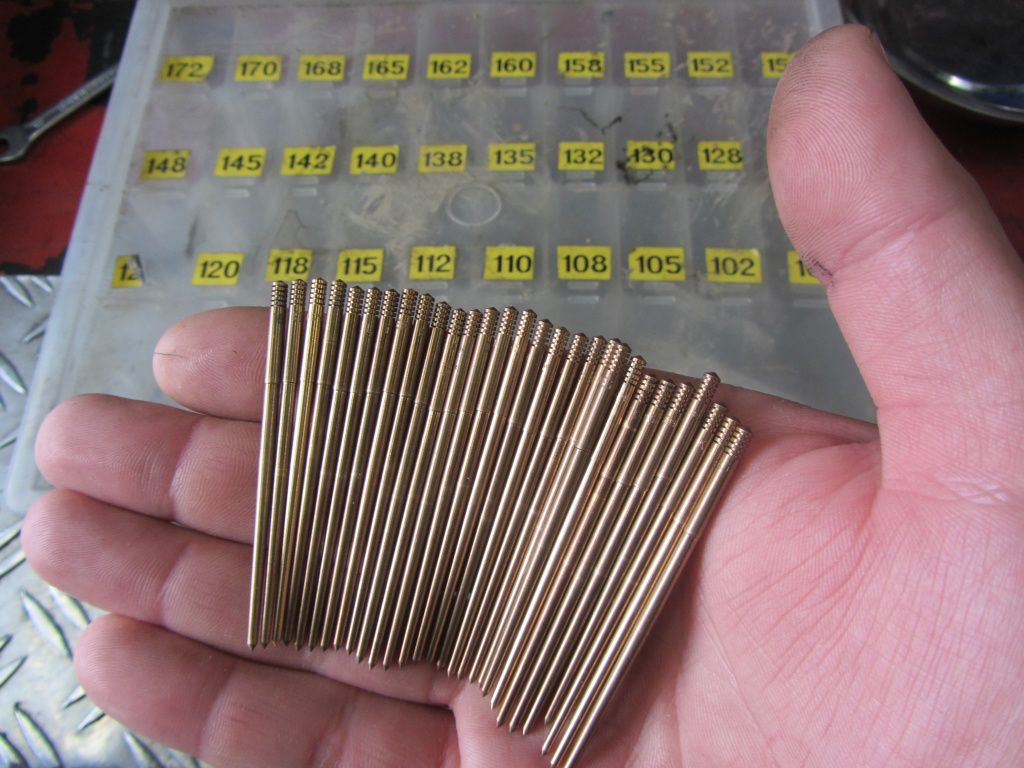

The needle is very important for a smooth engine run and picking the right one can be tricky. In our online shop, you can find our pre-selction of needles. All these are good working ones on scooter engines. Here you see our dyno colletion of the D needles only.

Kleine Auswahl an Keihin Nadeln

From our experiences and findings the DGL needle works very well on rotary valve engines. The DEK needle with which the Keihin 35 is delivered, is a little bit on the rich side low down.

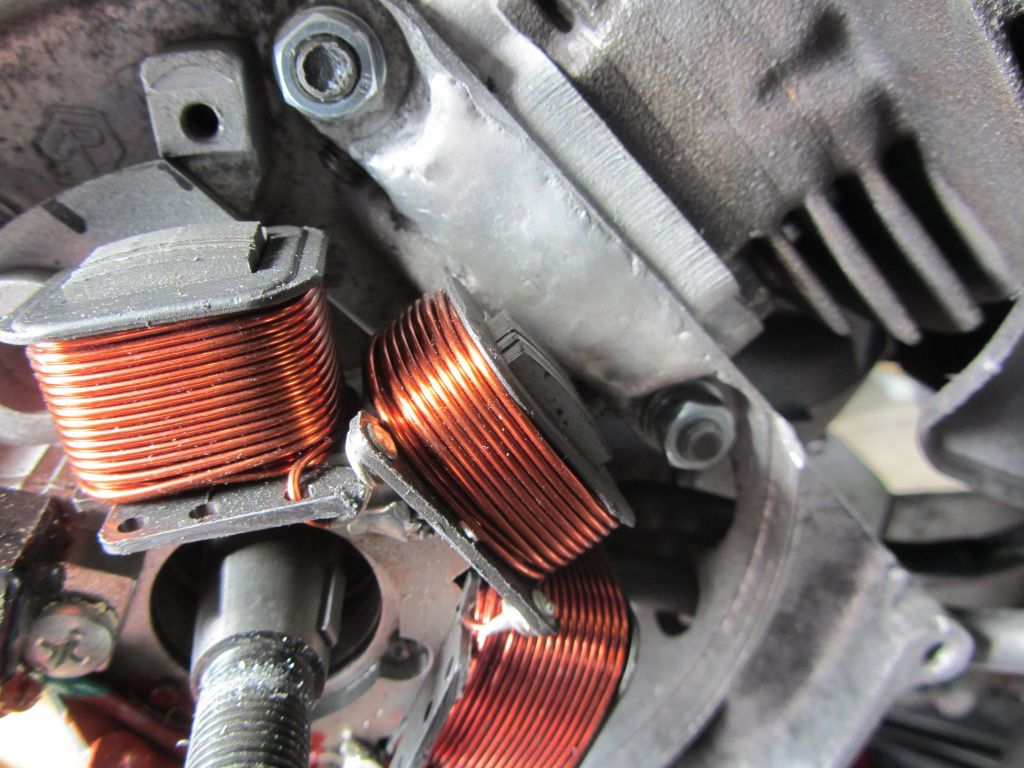

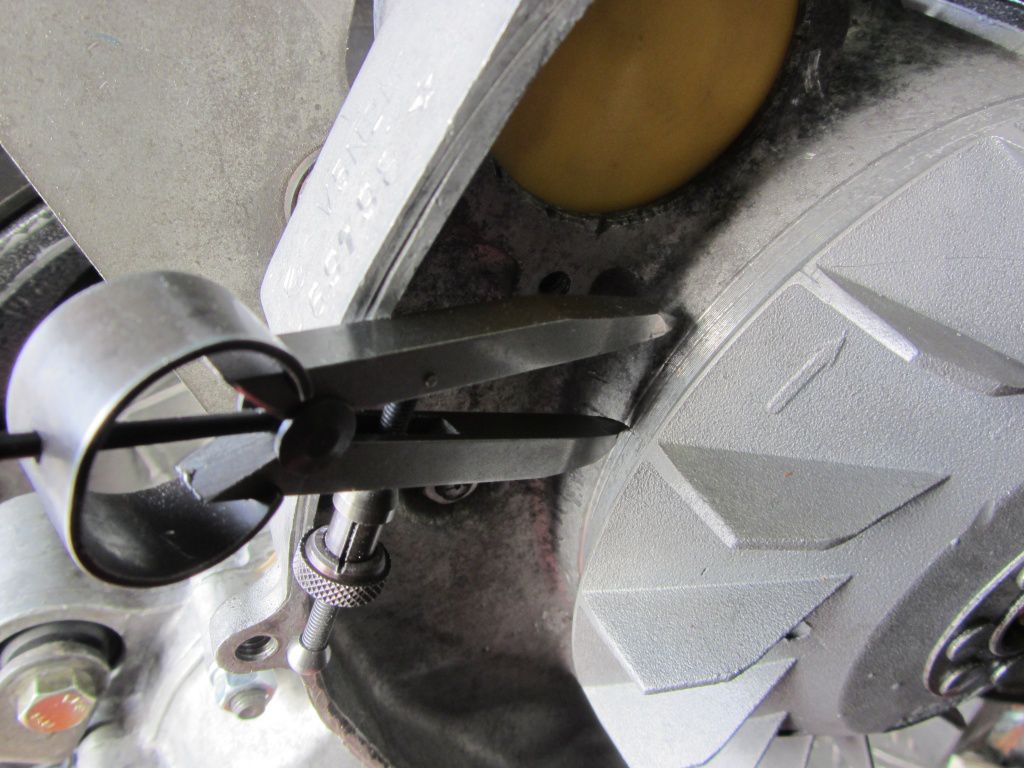

Next step is to check the timing of the ignition system. Vespatronic. Sadly the welded engine casing makes it necessary to modify the stator plate. And even more sad, it is where the ignition marks are and after the mods are done were.

We need to do new markings using a piston stopper. Using a piston stopper we fimitteln wir wie immer durch eine Umschlagsmessung.

We know turn the flywheel clockwise and anti clockwise untill it is blocked b ythe stopper.

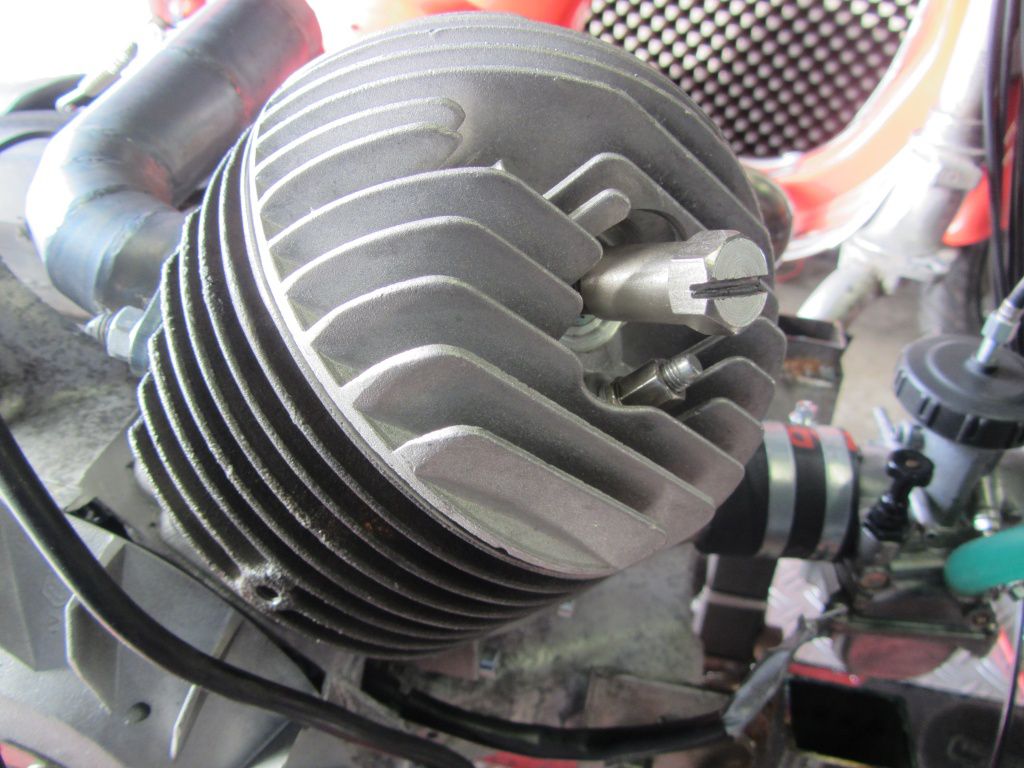

Kolbenstopper zur Umschlagsmessung

We know mark the stops at the casing with the arrow on the flywheel as reference. This need to natch exactly, sadly the camera doesn’t justice to this at the picture.

OT Markierung 1

We know need to find the middle between the two marks. This is our top dead centre.

After finding the top dead centre, we know need to figure out where our 18° pre-ignition settimng is.

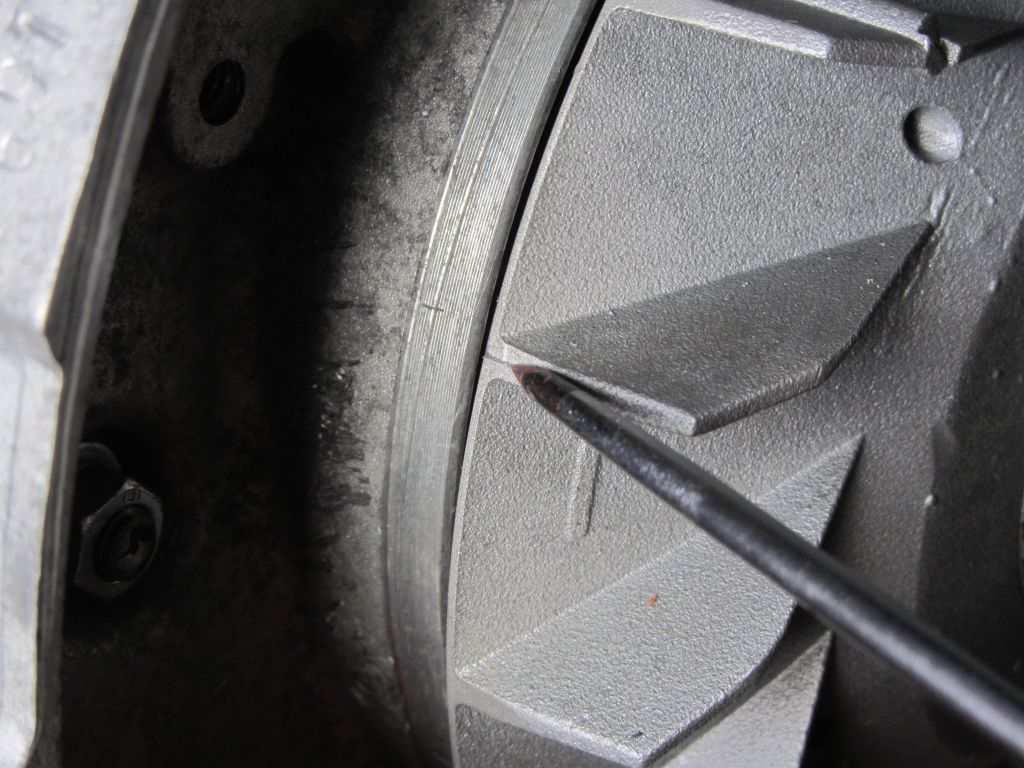

We measure the circumfarance of the flywheel.

This is 529 mm. If you divide this by 360, you know the mm of the circumfarance that equals 1°. We take this and multiplie it with the wanted 18°.

Here it is like this: 529/360*18= 26.45 mm.

We know measure this 26.45 mm on the flywheel starting from the arrow on the flywheel.

Know it is time to strobe the setting to be sure that everything is spot on.

We found the ignition timing is 16° instead of the 18°. We leave it as it is for the moment and idle the engine up for the first runs.

While warming the engine up and switching thru the gears, we find the 3rd gear jumps out. Damn! Okay, the solution for the moment is to measure it in fourth. Because of the higher gearing the power output is not as high as it would be in the 3rd gear. Which is normally used for dyno work.

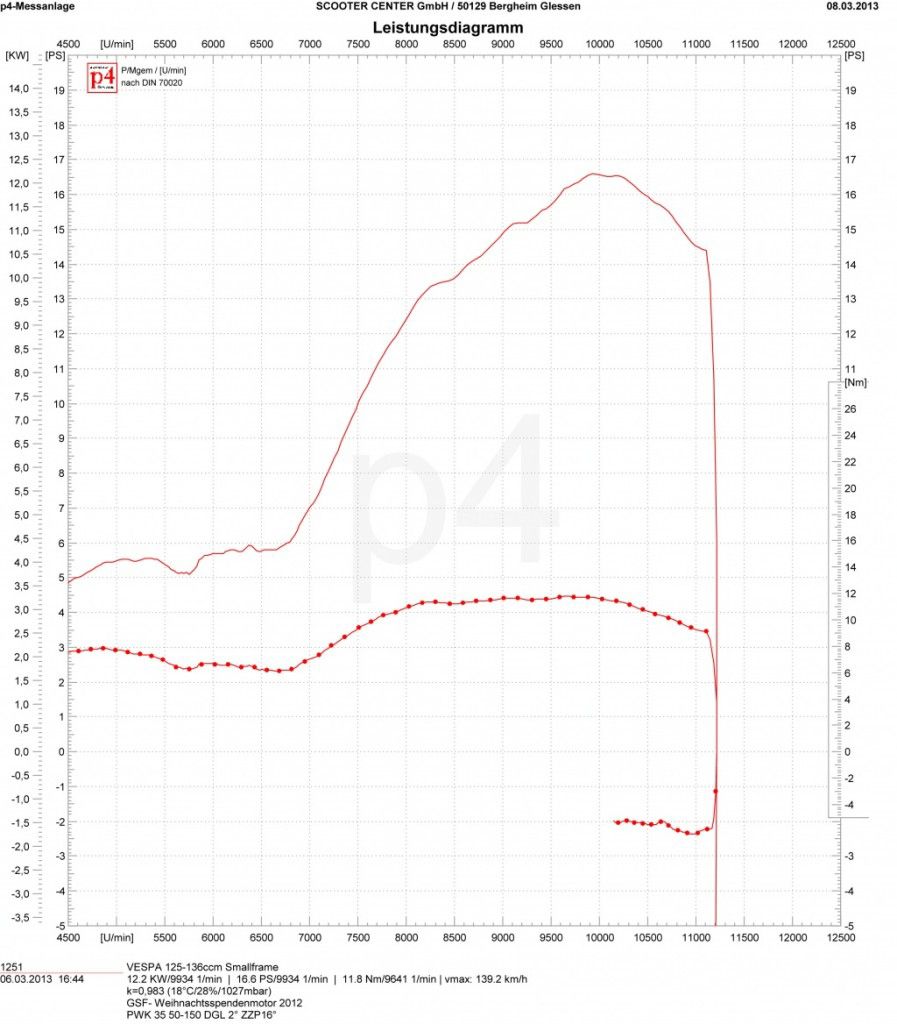

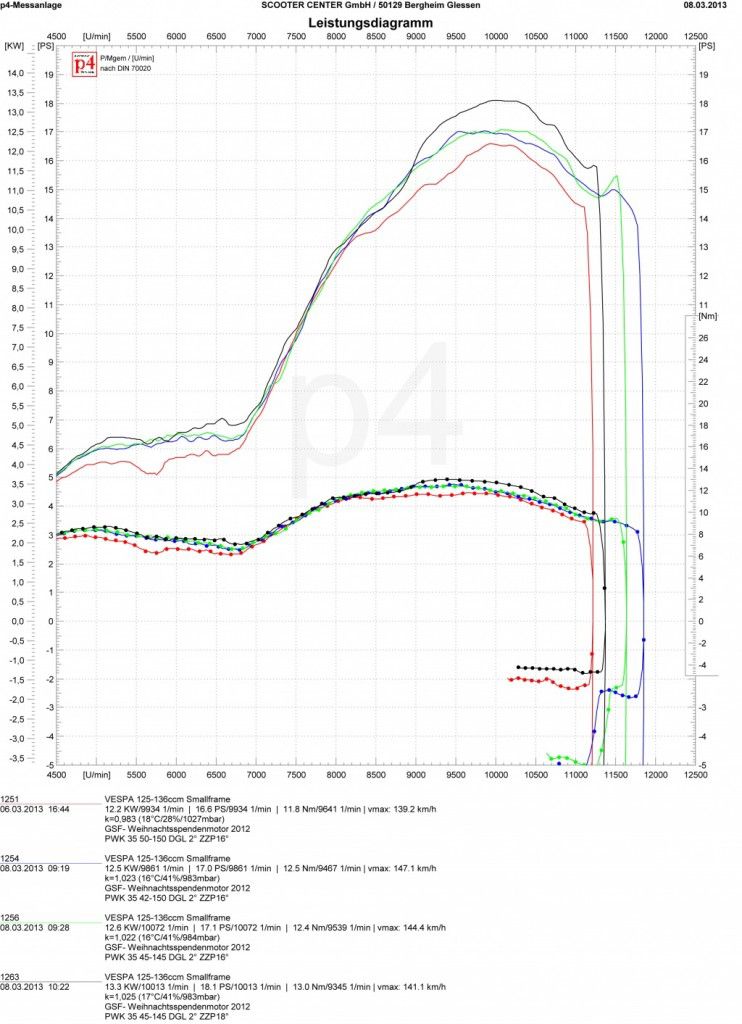

First try…

The carb setting is too rich. The power before the exhaust starts to work is very bad.

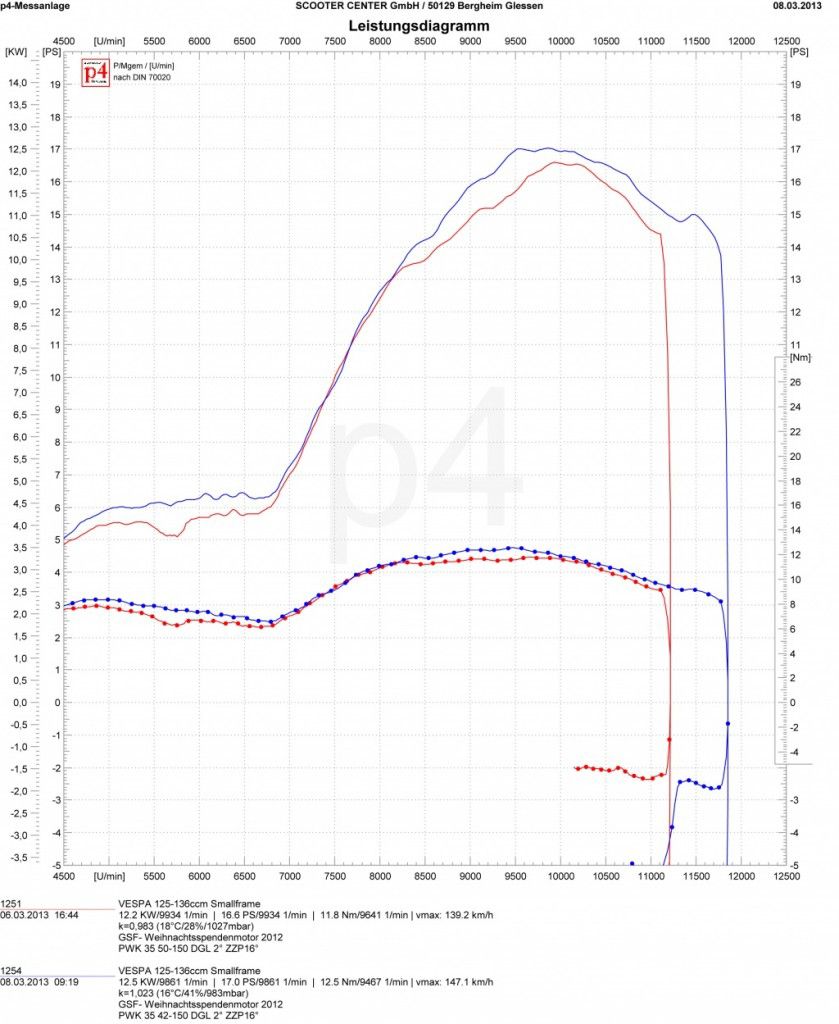

We change the idle jet to a 45 and see…

Because we are not 100% happyyet, we try the 145 main next::

We haven’t found more peak power. But the graph is much smoother and the engine responds much better to the throttle action. Something you simply can’t picture with a graph only.

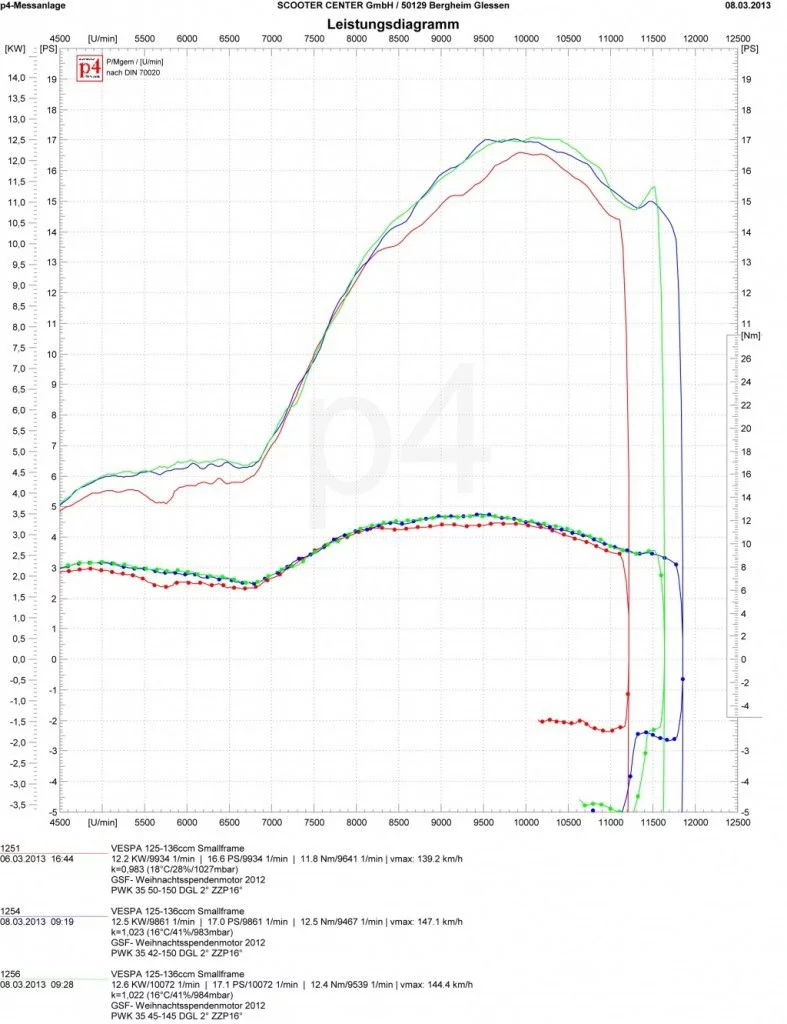

Now we change the ignition timing to 18°…

That was it, more power before the pipe starts to work, more peak and more torque.

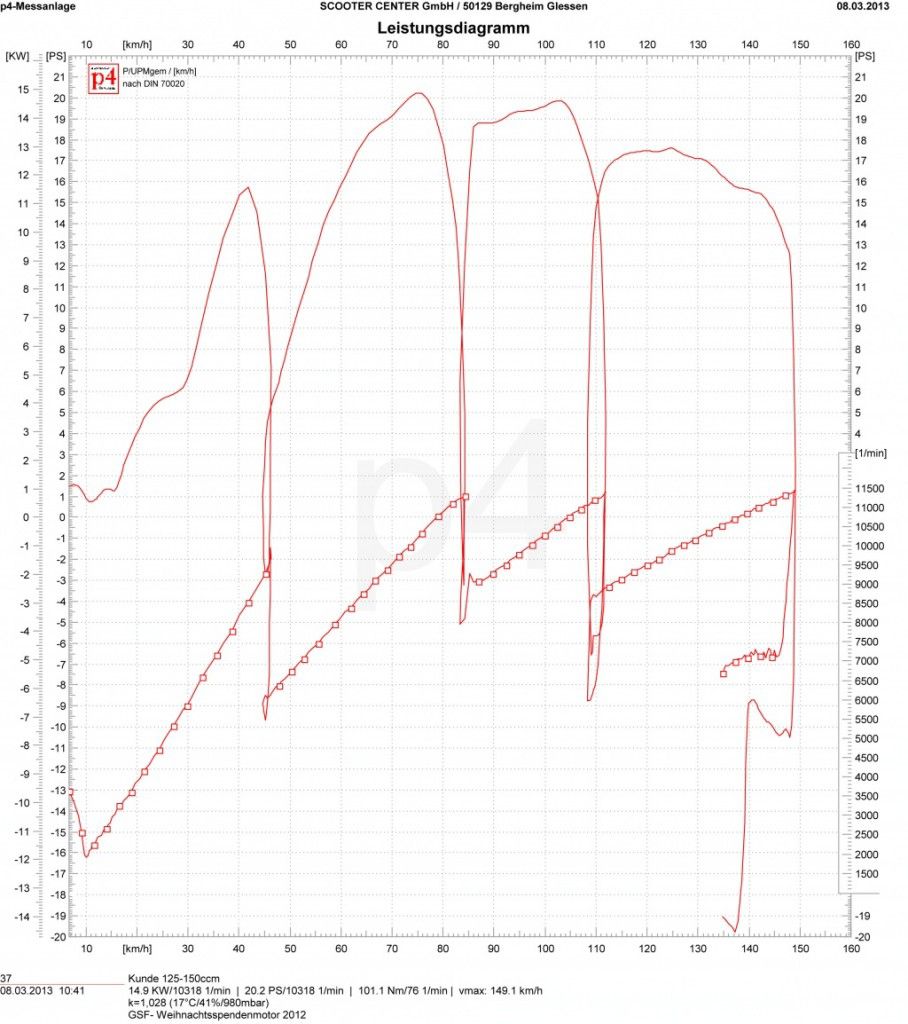

Now we finish with a run thru all four gears.

20 hp in third gear. Mission completed.

Hinterlasse einen Kommentar

An der Diskussion beteiligen?Hinterlasse uns deinen Kommentar!