The new 177 – cylinder for Vespa

We have already presented the new cylinder in this post. Today we would like to offer you an insight into developing this cylinder. The cylinder will finally be available from beginning of April 2016!

Developing the Vespa cylinder BGM177

Developing a two-stroke cylinder is very exciting.

Numerous parameters, which need to be considered, thousands of times on the dynamometer, a repetition of measuring, calculating, testing, thousands of kilometres on the road…

What for? To have a final cylinder, which offers high torque and is willing to deliver maximum performance, at the same time resistant with a low consumption.

And we want it all. A cylinder for tourers, which can be combined with standard components, and for ambitious tuners, who want the highest performance possible. It is about offering the widest range possible.

We would like to give you an insight in the tests, which have been conducted for the BGM177.

DESIGN OF TRANSFERS

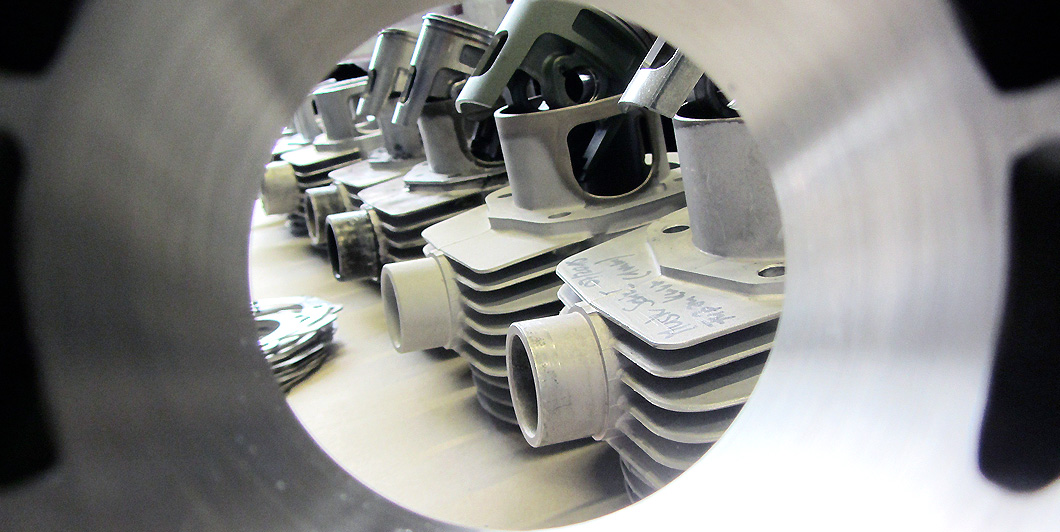

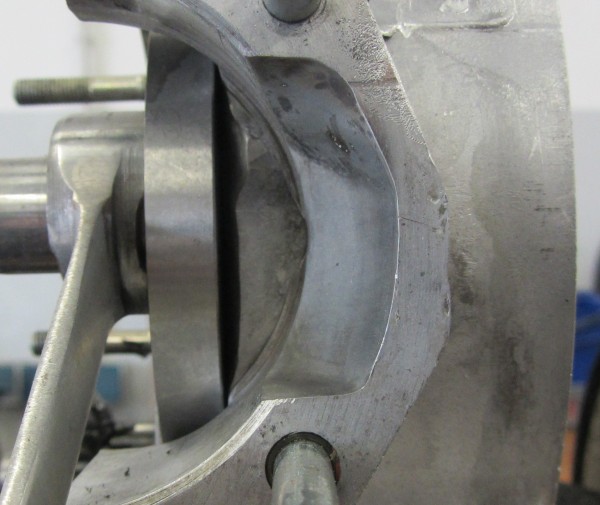

We tested various options for the outer design of the transfer ports.

We designed various transfer geometries, trigger delay angles and combustion chambers, which were put to practical tests on the road as well as on the dynamometer.

TEST ENGINES SPRINT150

We have been using an original Piaggio Sprint engine as starting point for our tests and for some we also have been using a LML engine casing with original inlet membrane control.

The Sprint engine casing represents the very small, original rotary valve inlet of largeframe engines. The rotary valve inlet of a PX125 is only minimally larger than the inlet of Sprint engines. Trigger delay angles of the crankshaft are almost the same. In terms of possible performance, this was the „least attractive“ package. However, we wanted to know the performance with basic parts or rather which performance we could expect of the rest.

We have already presented the comparison of a Spring engine with a 24mm SI carburetor of a PX200 and a 12HP 200 engine.

In order to easily understand the following graph, just imagine a normal PX200. With a standard 200cc you will feel something like acceleration up to a speed of about 90km/h. This speed represents about 5500min?¹ of the engine. Once you have reached this torque with a 200cc engine, it will take some time to get to 100km/h (6000min?¹). Now, take a look at the graphs and compare the equivalents of this torque on the blue graph and the red graph. You will see, that the BGM177 even adds more torque. In other words, while a 200 is slowly running out of steam, the BGM177 will continue to accelerate.

BGM177 vs. PX200

TEST ENGINE LML150 MEMRANE

The 125cc engine of a Vespa Sprint with small rotary valve restricts the development of performance at a certain level of performance and torque. We have therefore used a LML engine casing for varying tests and comparisons. The standard LML engine casings comes with a reed valve intake and large transfer ports in the casing and is the best basis. This can diminish the influence of e.g. an intake, which is too small, or differently designed transfer ports on the test results within one series of tests.

It’s also fairly easy to switch between a SI carburetor and a large, grown-up intake.

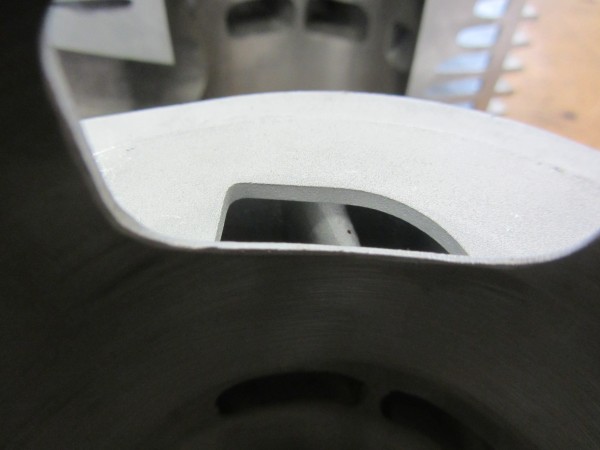

We have started these tests with a pre-series cylinder with small transfers in the cylinder base

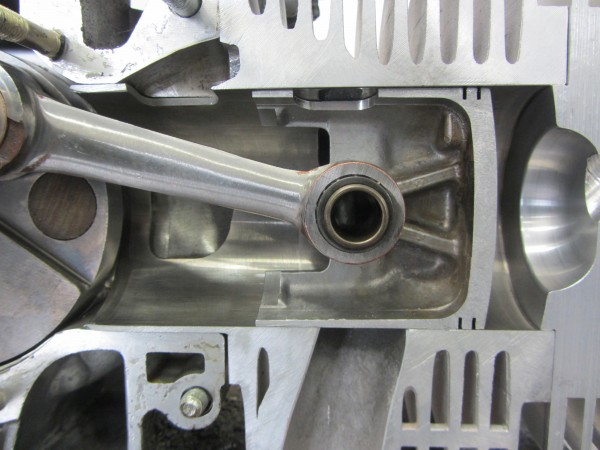

and a piston, which has been specially produced for this test.

Why? We wanted to find out how the piston needs to be designed in order to give enough room to the transfer ports to guarantee a good situation. The piston had been constructed in a way, that the hole around the gudgeon pin close to the transfer ports could be adapted by milling.

After every little step, we put it to the test on our dynamometer to find out, which shape or which combination works best.

TEST TRANSFER PORT CROSS-SECTION CYLINDER BASE

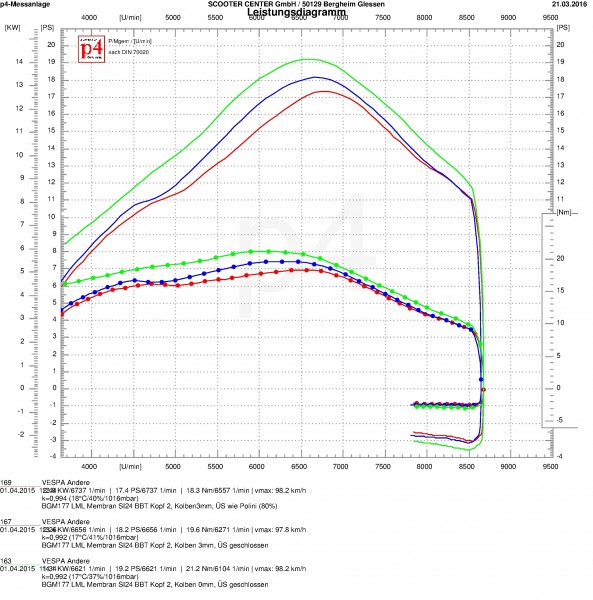

The following series of tests has been conducted on a LML membrane engine with a 24 SI carburetor, a BigBox Touring and various versions of pistons and transfer ports.

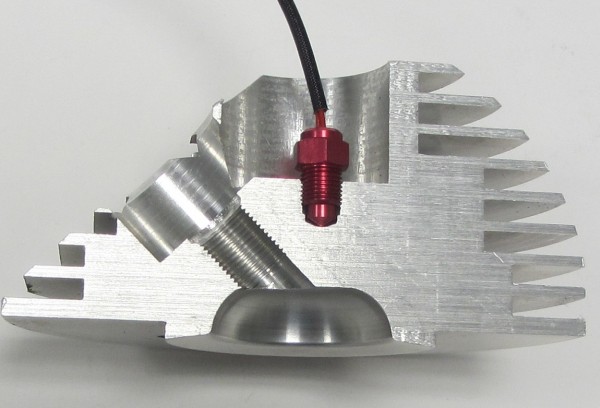

Then, the cylinder head has still had a relatively high compression. We have reduced compression of the standard cylinder head a little to gain a wider range of performance.

The original test piston was shaped like the original PX piston. So, for the red graph, the piston skirt was closed (like for a Piaggio, Polini, Grand Sport, …).

The blue graph shows the result of the piston with a few millimetres less around the gudgeon pin. You can see such a piston on the picture above.

The green graph shows the performance with a semi-closed transfer port at the cylinder base and an adapted piston. The free space of the transfer ports in the cylinder base represents about 80% of the possible space of the cylinder.

- RED GRAPH: closed piston skirt

- BLUE GRAPH: semi-closed piston skirt

- GREEN GRAPH: opened piston skirt

Result: the BGM177 can be combined with the gearbox of a 200cc engine without causing any problems and even performs better than the large 200cc engine.

From about 1982 onwards, engines of PX125 and PX150 have been fitted with a gearbox almost identical to the one of a PX200. In these cases it’s possible to directly extend the primary drive to transfer the plus of performance to speed.

We recommend using a primary drive wheel with 64 teeth. Depending on the area of use, you can adapt the total gear ratio with a clutch sprocket. The advantage of a primary drive wheel with 64 teeth is, that you may use the BGM clutch sprockets with 22, 23 or 24 teeth.

So you can set your engine for anything between „sporty and short for cities (22/64)“ and „highway – provide a maximum (24/64)“.

Our next post will be on various carburetors and intakes on our LML test engine.