HQ suspension components made in Germany by BGM PRO for Vespa Wideframe / Largeframe

Piaggio is known to many 'only' as the world's largest scooter manufacturer. The Vespa, as Piaggio's most outstanding brand, had a lasting impact on the image of the Pontedera-based company. Originally, however, Piaggio also manufactured railway wagons, ships and very successful aircraft engines (around 1940, double star 18-cylinder P.XV with multi-stage turbocharging, 1500hp takeoff power) as well as very innovative aircraft (1938, P.111 with pressurized cabin for a service ceiling of 12000m !) produced. The Piaggio Aerospace Group continues to build innovative aircraft such as the P180 Avanti on the beautiful Italian Riviera. The fastest twin turbo prop machine in the world with a cruising speed of 600km/h.

SIMPLE BUT GENIUS

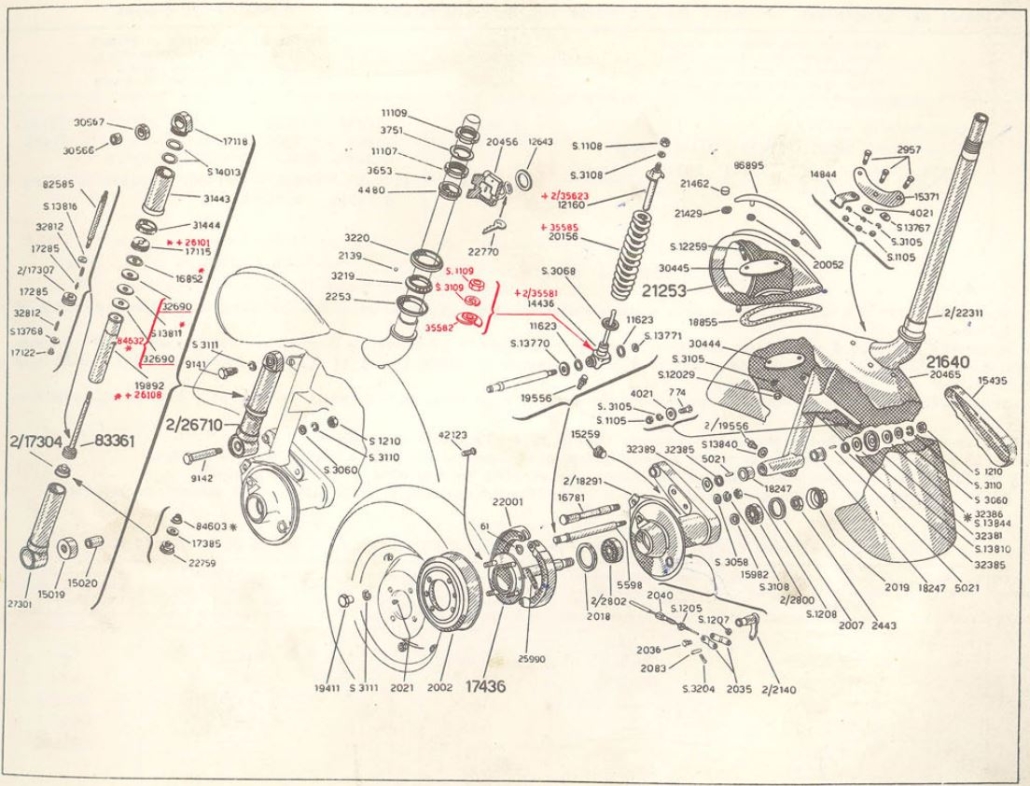

What does all this have to do with chassis parts for old Vespa scooters? Piaggio has always been high tech. You often hear disrespectful things like, 'the Italians just took what was lying in the corner'. Piaggio's greatest achievement, however, is the one that is almost completely unnoticed: the highest possible technical simplification with maximum efficiency, stability and the best economy. One of Piaggio's secrets, why the group is so successful to this day. Many things about Vespa scooters are brilliant technical solutions precisely because they are so simple. However, the structural performance behind it is usually significantly higher than with a more complex solution. The one-sided front wheel suspension, as used in a simple form on the Piaggio P148/149 training aircraft, is a good example of this.

AHEAD TO THE PAST

The one-sided wheel suspension enables quick wheel removal, has fewer parts than a two-sided wheel control and is also designed to be so stable that even generations later can continue to use the material and also often put much more stress on it than originally intended. Who would have thought during the construction of the front swing arm in Piaggio's engineering office that 60 years later(!) people would still be driving around twice as fast with this material and sometimes with 5-6 times the engine power? It's hard to imagine that someone will be driving around with today's Vespa GTS300 in 60 years with 100 hp and 240 km/h, isn't it? The fact that all of this works wonderfully is thanks to the technical foresight of the Piaggio designers, who still worked with the product quality standards of the time and multiple guarantees with regard to the component dimensions. So the old original Piaggio parts are still a 'bench' in terms of dimensional accuracy and resilience (a fact that unfortunately can no longer be fully applied to today's original parts).

ORIGIN & QUALITY

But what to do if the original part is damaged, worn out or even missing? Clear case, a new part is needed. However, many parts for early Vespa models are no longer available from Piaggio. Fortunately, the Vespa fever is a worldwide phenomenon and therefore the sources for spare parts are limitless in the best sense of the word. A fact that also raises problems at the same time... True to the motto 'many cooks spoil the broth', the qualitative selection of a product is also blessed with many pitfalls. Regardless of whether a repro component comes from Italy, the Far East or Germany, the quality has to be right.

However, some parts are often only available from a single source and then it's 'take it or leave it'? Shouldn't you offer a product at all because it doesn't quite match the quality of the original? Or do you sell it and point it out, at the risk that the pointer will not be noticed and a bad product review will follow?

A situation that is unsatisfactory for all parties. This also applies to the highly stressed components on the old Vespa steering tubes and swing arm.

THE SOLUTION FROM BGM PRO

Our solution: We analyse, measure and draw new components exactly according to the original Piaggio model and have them precisely manufactured in Germany by a specialized company. In doing so, we go one step further than Piaggio did back then. Not only do we use higher quality material, we also have it heat treated...

SWINGARM PIVOT (BGM4310 for Vespa Wideframe/Largeframe 1953-1962)

Suitable for Vespa Wideframe VM, VN, VL, VB, GS 150 (VS1-5T), Largeframe VNA, VNB1-4, VNB5T (-026920), VBA, VBB1T, VBB2T (-212455), Vespa GL (VLA1T, -067468)

A difficult word to read and yet so important. This component connects the steel steering tube (also known as the head tube or fork) with the aluminum swing arm. The latter guides the wheel and also connects the damping/suspension to the steering tube. Any wheel force, any steering movement, any up and down movement of the wheel is transmitted via this axle.

In order to not only do justice to all of this, but also to take care of today's demands, we have the BGM PRO swing arm bearing axles made of high-strength premium steel (1.4112 alternative designation X90CrMoV18). We attach great importance to precise compliance with dimensional accuracy. The axes are precision turned to a surface finish of 0.2-0.4RA:

The material quality, surface and corrosion resistance would already make the axle stand out from any mass-produced product and even from an original Piaggio part.

However, we also have the axles plasma-nitrided. This gives the axles a harder surface and the bearing points will certainly not run in over the life of the scooter. The nitration also gives them their characteristic matt coloring (however, this can also be polished away). In summary, the BGM PRO swing arm bearing axles are without exaggeration the best on the market and, with their high quality, offer great security, especially for performance-enhanced vehicles.

The dynamic loads on a vehicle often do not increase linearly with speed, but often even quadratically. If you drive a vehicle twice as fast as originally intended by the manufacturer, you can generate loads that are four times as high. Another reason to be on the safe side with the BGM PRO swingarm bearing axle.

BRAKE PAD BOLT (BGM4311 for Vespa Wideframe/Largeframe 1949-1962)

Suitable for Vespa Wideframe V1, V11-15, V30-33, VM, VN, VL, VB, GS 150 (VS1-5T), Largeframe VNA, VNB1-4, VNB5T (-026920), VBA, VBB1T, VBB2T (-212455), Vespa GL (VLA1T, -067468)

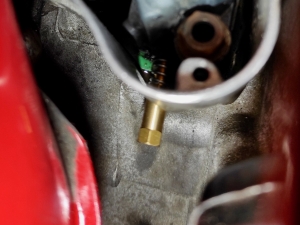

What sounds relatively harmless here is also a component that deserves closer attention. The pad bolt is much more than its name would suggest. It forms the support for the chassis spring on the swing arm. Where relatively soft springs were used at the factory, today there are taut sport springs and greatly increased speeds as well as often one or the other stunt, such as riding on the rear wheel. The often rough touchdown of the front wheel after such a wheelie makes it difficult for the brake pad bolt. It is not particularly large ex works, but it has a grease nipple. This can be used to regularly lubricate the highly stressed point between the spring retainer and the brake pad bolt. This should also be done as far as possible, but how many people with such vehicles do you know who even have a grease gun that is necessary for such purposes?

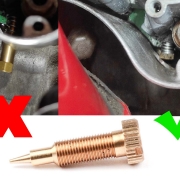

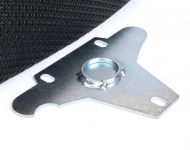

That is why the same effort was put into this as with the swingarm bearing axle; Extremely high-quality material whose surface has been further refined to be even more durable than the original component. In the case of the bolts for the later models with clamping plates (from around 1969) we have also eliminated another annoyance of many replica bolts; The lack of dimensional accuracy with regard to the length of the bolts and the inappropriate shape of the recess in the clamping plate. Many bolts are often a few tenths of a millimeter too long or short. This is solved once and for all with the BGM PRO brake pad bolt:

This is always the right length*. Actually everything is a matter of course, but in the case of cheap reproductions, they go over the edge for cost reasons. Like the swingarm bearing axle, the brake pad bolt is also finely turned from high-strength premium steel (1.4112 alternative designation X90CrMoV18) and then plasma-nitrided. With these products, we want to give a new face to the sometimes overused phrase 'Made in Germany'. That this is not possible at prices like in the Far East can certainly be understood. In return, we can offer a product that is unique and of extremely high quality, and we are sure that every customer will enjoy it as much as we do.

*NOTE: Spanish (Motovespa) and French (ACMA) vehicles have a slightly different length measurement at the pad stud. Here the fastening nut can be lined with an M8x1mm washer to guarantee a perfect frictional connection.

The swing arm pivot and brake pad bolts for the later models (Largeframe 1963-1979) will follow in the coming weeks!

BGM4310- swingarm pivot Vespa 1953-1962

BGM4311- Pad bolt Vespa 1949-1962