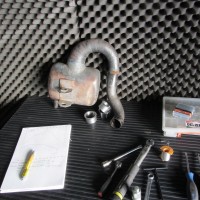

Vespa Polini 210, BGM 60mm, Dellorto SI26 - tuning test engine - Pt. 5th

Only a few steps left untill we can dyno test our new engine.

The engine will go into the Silver Fern and be tested for Rally going and daily commuting then.

While fitting the flywheel care must have been taken that the slot in the flywheel cone aligns with the woodcall key.

Afterward the flywheel groove can be tightened down to 65Nm. the washer needs to be fitted, otherwise the nut will come loose.

The rear brake drum goes on the shaft next. We only put it on loose and fix it with the nut.

As soon as the rear brake is adjusted we will tighten it down to 110Nm. Securing cage and splint must be there.

For adjusting the clutch you need a little bit play at the clutch lever. This should be around 1.5mm and 2mm.

Oil and fuel hose are connected. consequences. The air bubble at the oil hose is a very good indication to see if there is oil pumped into the carb.

But the air bubble shouldn't be much bigger than that. Otherwise there is the risk that the oil pump runs dry. And so will do the lubrication then.

For the first firing we fill the fuel tank up with 1 liter of oil petrol mixture of 4%. This should be done to have a proper lubricated engine from the start and to compensate the oil pumps delay.

The engine starts and we let it idle for a while. Then we see that all cables are connected properly. We round down to fourth and everything is okay. The clutch works perfect. And the oil pump operates as well.

So we are ready for the first dyno sessions. Watch this space.

excuse me sir. i have question ...

i have marlossi 210 vespa (210cc / si26 / polini air intake / 140 mainjet) ...

How do turn the mixscrew ??