Nice video of a Vespa: Supermoto vs racing - Vespa.

Recorded on the Pannonia Ring:

Nice video of a Vespa: Supermoto vs racing - Vespa.

Recorded on the Pannonia Ring:

The clutch bush is not just an underestimated part of the engine, it is a part as well where we found the aftermarket parts and even OEM parts not capable of doing the job properly.

The bushes made from sintered metal are not the best choice for tuned engines with ore power available on the tap, gear changing at higher revs

Power, switching points at higher speeds and light flywheels bring the simple sintered metal bushings * available on the market to their load limit. Chattering clutches or jumping leapfrog when starting up are often the symptoms of a worn-in or damaged socket.

Special requirements call for sensible solutions. The bgm PRO coupling socket is “Made in Germany” and made of solid material. The material withstands the high moment forces and is specially designed for plain bearings with little lubricant.

The circumferential lubrication groove distributes the oil evenly over the bearing surface of the bushing so that lubricant is immediately available when the clutch is actuated.

Our BGM PRO coupling socket is suitable for almost all coupling hubs of the Vespa Largeframe Models. Due to the very tight tolerance during production (we allow 0.03mm), even slightly worn hubs can be repaired with our bushing.

For repair purposes, the hub should still have a diameter in the range of 24,02mm - 24,06mm.

For sure all the bgm PRO SUPERSTRONG Clutches are equipped with the new Made in Germany bush.

Legendary exhaust for the Vespa PX and T5 models, in Taffspeed's known premium quality!

Vespa exhaust system in the unbeaten Taffspeed quality:

This fine piece comes with the exclusive "Scooter Center"Imprint, plus it features the engraving found in the" TÜV "certificates for all PX 200 GS (9 kW) models until 1996.

With an exchanged manifold, you can use this expansion chamber on all PX 80-150, PX and T5s.

The fantastic workmanship makes the MK4 the most durable exhaust. Fortunately, the muffler can be additionally insulated without sawing and drilling holes. Just remove the retaining ring and you're good to go.

In addition, the MK4 can be used with a spare wheel, if the latter is shimmed sufficiently to provide enough clearance from the frame.

Conclusion: Perfect all-rounder with loads of torque and a very nice muffled sound!

Exhaust | Racing snail | Silencer | Sound box | Pouf | Pot | Horn | Muffler | Exhaust system

Not long until the first ESC races are started. Good for the ones who have their racing machines already sorted out and are waiting now. True to the motto: "Racing is life anything that happens before or after is just waiting."

If you haven't done your preparation yet, it is time to start things for the racing series everywhere.

We too have to build an engine. This will be used for the class 2 of the ESC. This is the cream of the crop class at the Euro Scooter Challenge. Nothing is hidden here and most things are allowed as well. All info about it can be found here: www.eurochallenge.de. The only restrictions that can be found is no larger capacity than 150 cc, while the top notch engines have a power output of 35 - 38 hp at the rear wheel.

On most of these engines you'll find the stroke of 53 mm combined with a 60 mm bore what gives 149.85 cc. This formula for power and success is used on our engine as well. The Falcon cylinder kit with 60 mm bore and a special made 53 mm stroke crank will be put onto the Quattrini engine casing.

We don't want to keep back this awesome panorama of all the parts that make such a nice engine ...

… And we did a nice shopping list for recreating this view in your living or sleeping room. Wherever you like it more. This is the download file CSV file that you can upload to your shopping basket in the online shop.

Before we are even think about putting all the parts together, everysingle one gets a closer inspection. With such high power outputs even small mistakes can cause big trouble. If it happens while racing the trouble gets even bigger. Because racing is life, anything else is just waiting to bring this saying. Because we have used parts that are going to the engine, we take double care.

At the casings we start with checking the gasket surfaces and bearing seatings. the Christmas tree is not really free running ...

And fitting like it would cause problems. Latest if the bearing has been fitted. One more to watch: If you are on the race track and have to change the gear ratio a larger gear wheel would cause real problems. And this is nothing that will cure itself during running.

The clearance needs to be milled much larger to easily get the Xmas tree out and to fit taller gearing when this is needed.

At least we are so lucky that there are no further surprises in the bottom end.

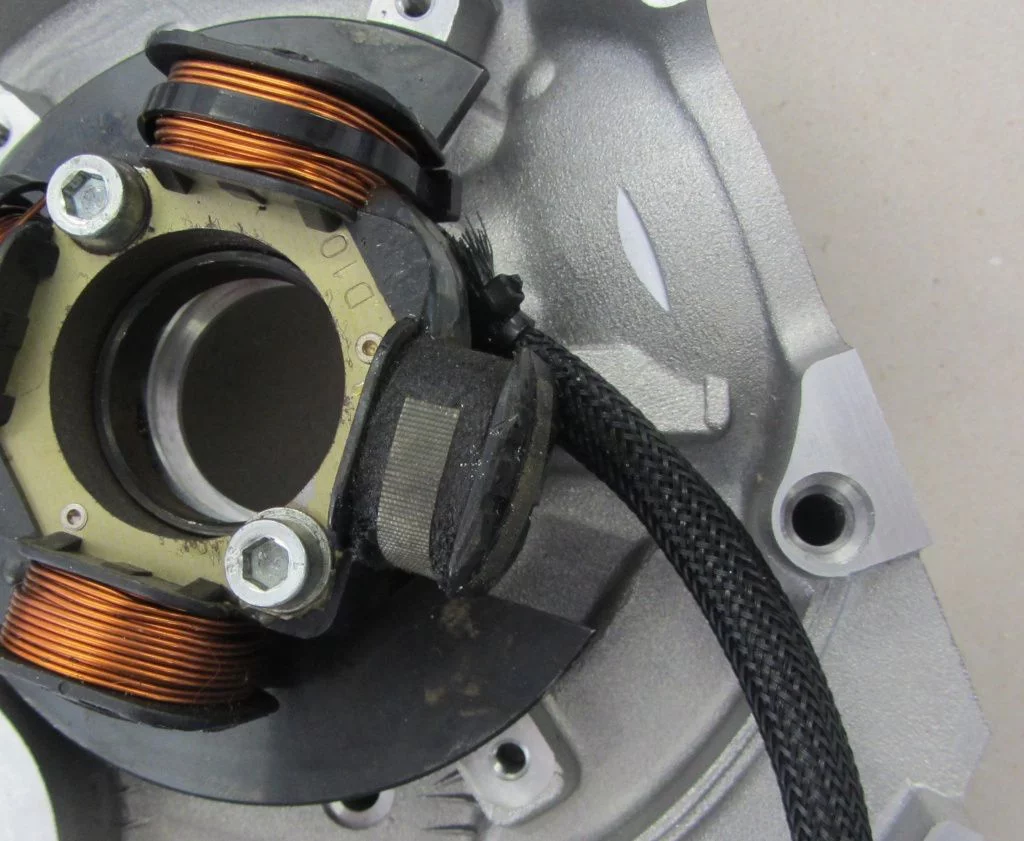

The small casings helped give some nice little perfidy though. Normally you fit the stator plate of the ignition kit, take the cables put it through the hole for the cable. But ... wait ...

This is special, maybe this construction is for one of those WIFI ignitions. Where you no longer need wiring loom for the stator plates. Who knows? Anyway we opt for taken out the drill and get this sorted. The design of the original engine casings gives a good indication where to drill the hole makes sense.

As a protection for the stator wiring loom we take the rubber of the V50.

The right size for this is 12.5mm. For bore holes of more than 10 mm a good practice is to use a smaller drill to get the things done step by step.

... and then you can work your way up to the desired size.

Chamfering done and then a quick try on.

Everything is spot on. Now the dirty work on the small half of the casing is done.

Next we check the area of the top end for any design faults or imperfections that need to be sorted out.

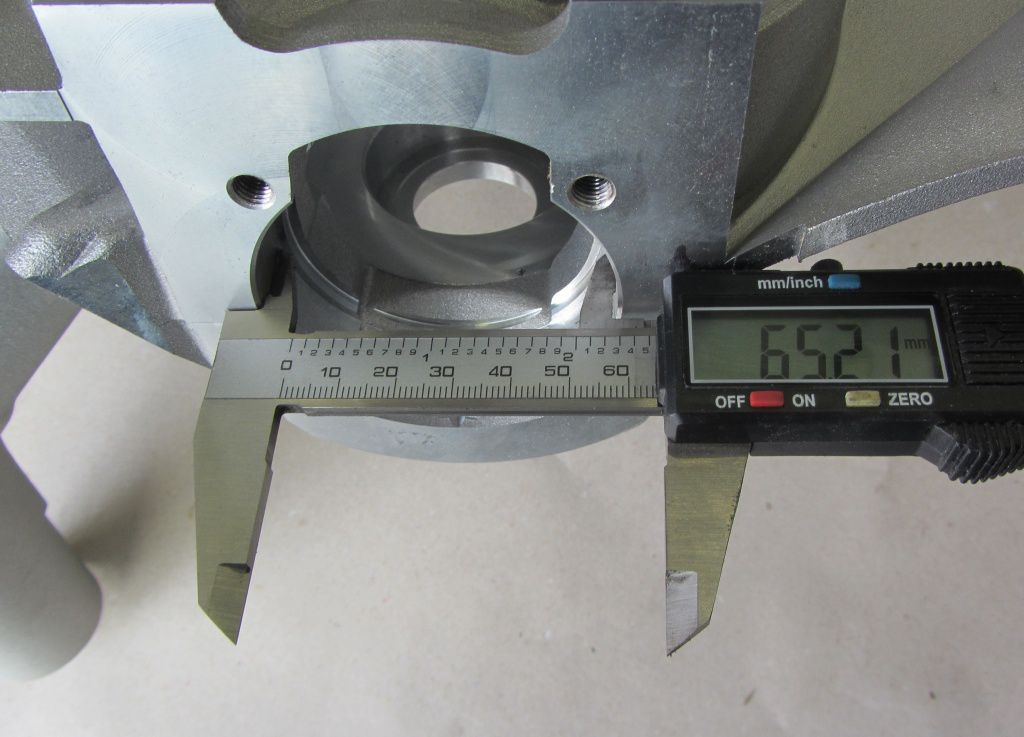

While the Falc cylinder kits are manufactured with a diameter of 66.5 mm, the Quattrini engine casings are machined to a diameter of 65.2 mm suited to the Quattrini cylinder kits. Standardization on these thing would be to nice. Why isn't it simply done in a way that items that were on the market earlier also fit?

So we know it's up to us what we do. There are two options that need to be considered:

1. The neck of the casing can be machined to the diameter of the casings.

2. The cylinder can be machined down to a new smaller diameter.

We opt for the second one.

If one wants to any other cylinder kit In future times, this can easily be done. The thickness of the spigot is more than enough.

After the barrel is machined down we check that it really fits and everything is spot on. That is the case and we can now see what needs to grind out at the transfers.

Very close to perfection! Just the cylinder needs to be matched very slightly to the surface are at the casings. The casings leaves at it is for the moment and we check port timings before anything else is done to the casings.

The engine casing comes bare without any silent bushings fitted. There are lots of solutions for this on the market. Some make more sense, other not so much. If the rubber is to stiff it is nice for going on fast and long straights. But as soon as you need to take some fast cornering those hard rubbers are no longer suited for the job. For the rubber it is the same as for the suspension: "As hard as necessary, as soft as possible."

Because this is done for the circuit we use the silent rubbers of the V50 / Primavera with roughly 50 50 shore hardness.

Even on a quick look it comes clear that the bed stop for the rubbers is not dimensioned right. With high side forces put on the rubber these could be pressed deeper into the casings. To prevent this we fit the stops of the PK range models also.

Here you see the too small bed stop:

The stop of the PK range is simply put into place and prevents the rubber from getting forced deeper into the bore.

The relatively soft rubbers can be easily put into place using a little bit of talc or mounting paste.

For the rear shocker support we use our own rubber together with the original bushing

Compared to the original Piaggio rubber bear are a little bit wider ...

... and they match better to the casings. This gives a better side support.

The next episode will show how we fit the bearings and how to level up the crankshaft. Watch this space!

The first series of the Vespa V50 differs in some details to the later version that is much more common.

The early V50's for instance have the frame numbers V5A1 * 1001 * up to * 92877 and V5SA1 * 1001 * up to * 15325 *.

Differences of the first series are the suspension, the fixing of the rear brake plate with M6 studs, the three speed gear box, the 9 inch wheels or the shorter wheelbase. There are lots of small differences and the engine is unique as well.

If it comes to give this a little more power, there are some things that should be considered.

The original engine put out slightly more than one horse power (1.2 hp to be specific). This in conjunction with a very tall primary drive ratio 3.72 and a very big gap between second and third gear make this engine anything else than a good performer.

So if you want to use the first series for anything else than collecting dust, fitting a larger cc cylinder kit is very advisable.

The cylinder neck and the engine casings are smaller on the V50 1. than on the later models. This makes fitting of all the cylinder kits impossible. To cure this problem we have a ready machined cylinder kit on offer.

It's the Polini 75cc kit in the so called Racing trim. With a good power band and a maximum power of 4 hp it is the right choice to pull the tall gearing. The good power band even copes with the large between 2nd and 3rd gears.

The cylinder base is machined to fit the smaller diameter at the casings

The cylinder base is machined to fit the smaller diameter at the casings

Included in our cylinder kit is the speed nut M6 for fixing the flywheel cowl and cylinder cowl. This is necessary because the mounting points are on a slightly different place on the first series.

Polini recommends an ignition timing setting of 17 ° for this kit. If you are still using the contact breaker ignition system you can use a testing lamp to set the ignition timing at 1.4mm before to dead center.

Depending on the exhaust used and if a racing sickly has been fitted you should adjust your main jet accordingly to it. The fitting instruction of Polini says a main jet of 66-68 for the SHB 16 is right. We found that a main jet between 74-84 is right.

These carb kits are a good choice for the cylinder kit:

If you have to give the engine a going over anyway to replace the usual suspects like wear & tear parts as the gear selector, gaskets and oil seals, you should think about fitting a Rracing sickly ...

more short 3rd gear

The racing crankshaft gives a better filling and chance a higher torque figure. The shorter third gear gives a better gap between 2nd and 3rd gear and makes steadier accelerating and riding two up much more fun.

Modern day cylinder kits and full expansion chambers give amazing power outputs to the Smallframe vespa Setups like the Polini Evo used with the Big bertha expansion chamber like on ours Generation XI, give more than 24 Nm torque at the rear wheel.

To get the power from the top end to the bottom emd you have the clutch unit. With the high power outputs the clutch is under enormous stress. This connection has to be built with the care needed to get it reliable and long lasting.

Good practice these days is to grind in the clutch on the auxiliary shaft with valve grinding paste and afterwards to tighten down the primary drive and clutch nut to 70 Nm.

Specially for these high torque settings we have clutch and primary drive nuts in high tensile steel. These even sustain torque settings much higher htan 70 Nm. Because these are collar nuts that are usually used securing washers are no longer needed. Good practice is to use screw retaining glue.

To avoid any damages to the clutch basket and primary drive while putting such high torque figures thru the wrench, we have a new clutch holding tool now.

With this new tool inner baskets of the V50 / XL1 clutch

As well clutch inner basket of the PK XL2 can be locked for tightening down the nut.

The usual blocking of the primary drive the force put into the engine components is so high that they can easily be damaged.

Our clutch holding tool can be rested against a nut on the primary drive or against a screw fitted to the thread of the engine casings.

So the high torque figures are not transmitted to the bearing seats or the cushion drive.

So the high torque figures are not transmitted to the bearing seats or the cushion drive.

with our multi-tool the clutch can even be assembled while fitted in the engine.

To do the first dyno runs, we just had to fit the cables. You might remember?

The engine came at least the idle and main jet, while the needle were missing.

The needle is very important for a smooth engine run and picking the right one can be tricky. In our online shop, you can find our pre-selection of needles. All these are good working ones on scooter engines. Here you see our dyno colletion of the D needles only.

From our experiences and findings the DGL needle works very well on rotary valve engines. The DEK needle with which the Keihin 35 is delivered, is a little bit on the rich side low down.

The next step is to check the timing of the ignition system. Vespatronic. Sadly the welded engine casing makes it necessary to modify the stator plate. And even more sad, it is where the ignition marks are and after the mods are done.

We need to do new markings using a piston stopper. Using a piston stopper we mean, as always, by a reversal measurement.

We know turn the flywheel clockwise and anti clockwise untill it is blocked by the stopper.

We know mark the stops at the casing with the arrow on the flywheel as reference. This need to natch exactly, sadly the camera doesn't justice to this at the picture.

We know need to find the middle between the two marks. This is our top dead center.

After finding the top dead center, we know need to figure out where our 18 ° pre-ignition setting is.

We measure the circumference of the flywheel.

This is 529 mm. If you divide this by 360, you know the mm of the circumfarance that equals 1 °. We take this and multiplie it with the wanted 18 °.

Here it is like this: 529/360 * 18 = 26.45 mm.

We know measure this 26.45 mm on the flywheel starting from the arrow on the flywheel.

Know it is time to strobe the setting to be sure that everything is spot on.

We found the ignition timing is 16 ° instead of the 18 °. We leave it as it is for the moment and idle the engine up for the first runs.

While warming the engine up and switching through the gears, we find the 3rd gear jumps out. Damn! Okay, the solution for the moment is to measure it in fourth. Because of the higher gearing the power output is not as high as it would be in the 3rd gear. Which is normally used for dyno work.

First try ...

The carb setting is too rich. The power before the exhaust starts to work is very bad.

We change the idle jet to a 45 and see ...

Because we are not 100% happyyet, we try the 145 main next ::

We haven't found more peak power. But the graph is much smoother and the engine responds much better to the throttle action. Something you simply can't picture with a graph only.

Now we change the ignition timing to 18 ° ...

That was it, more power before the pipe starts to work, more peak and more torque.

Now we finish with a run through all four gears.

20 hp in third gear. Mission completed.

This is the final report about our pre-Xmas dyno shootout!

The 29.9 hp at the rear wheel of a Cast polini 133 cylinder kit with 54mm bgm sickly, Keihin PWK35AS carb and Fire magic exhaust had to be bettered.

With 29.3 hp Jonas did very well, but missed the goal. Followed by Mathias with 29.2 hp on a Polini 133 rotary inlet engine.

Together - Jonas and Scooter Center- decided to donate the € 100 shopping voucher for “Scooterist-chairty / GSF fundraiser.

Scooter Center likes the idea and is addiotionally offering free dyno time to set up the charity engine.

The gallery shows the atmosphere of the dyno shootout. Something that will hopefully continued very soon. What do you think? Fin .

.

Because virtual reality can hardly ever beat proper live action, we recommend to have a look at the small but mean Smallframe engines the next time.

Thanks to all the people who dropped in during the day. It was pure fun and we hope to see you soon!

[nggallery id = 19] [nggallery id = 18]Scooter Center xmas final. On the last two Fridays before Christmas, 14th and 21st December 2012, we invite all of you to our shop in Glessen between 10am and 5pm. Program for you:

· Dyno competition in different categories

· Irish Coffee

· Warm pretzels

· Hardcore engines

20% discount in our shop (codeword: Xmas)

· Who beats Alex on our dyno? *

*With a Smallframe up to 140cc (one exhaust and regular intake)!

From now on all bgm Super Strong clutches are equipped with our new bgm Pro clutch springs.

Of course our bgm Pro XL springs also fit in all other Cosa clutches from Piaggio, MMW and Newfren.

The springs are made in Germany from the material Oteva70 ®, a material which is specially designed for high dynamic loads, block resistance and high frequencies.

Because of its properties, the material is typically used in high quality valves and springs.

This means in the case of our Vespa clutch:

- practically no fatigue slope, the strain of the spring remains constant bgm Pro.

- bgm Pro springs are stable block. That means even if the spring is compressed repeatedly to the extent, the spring returns back to its original length.

The pre-tensioning remains the same.

Our bgm Superstrong clutch, equipped with bgm Pro XL springs also resists Largeframe engines with 25 Nm torque on the rear wheel.

Good tools bring even more fun to the workshop. Jobs aren't a mess anymore and can be done properly.

Our bgm multitool bgm8819 contains bgm8811 and bgm8812.

The bgm8811 tool is the flywheel extractor (M28x1) for all Vespa scooters with electronic ignitions. Starting at the OEM PX flywheels to the electronic conversion for the Vespa Sprint/VBB and V50/Primavera. At the same time it is a clutch extractor tool for the Vespa Smallframe.

Together with tools bgm8812 it gets even more complete. Because you have the clutch compressing tool too. And it is a very clever clutch tool too. You can replace clutch plates with the clutch still fitted to the engine. Cell phone, eh?

Especially handy, because you don't have to lock up the primary drive any more to get the clutch nut undone. If you have a 12 spring PK-XL2 clutch you will love it even more when everything stays in place.

The clutch compressing tool fits all PK and V50, PV, ET3 and the Polini double spring Clutches with 3 and 4 plates.

After the clutch cover and the pressure plate are off, tool bgm 8811 is screwed into the thread.

Afterwards clutch compressing tool bgm8812 comes on top.

And the nut, washer and screw (part of tool bgm8811) are used to compress the clutch.

As soon as the steel plates are spinning freely the securing clip can be taken of. Now you are ready to replace the plates.

Before the tool will be released the oil guide plate and -important! - the securing clip need to be fitted.

Job done!

Our test engine is running, we let it warm up properly. The jetting seems to be right with idle jet 48/160, air correcter jet of 160, atomizer BE3 and main of 140. So now we will see how powerful this engine is.

First of all the gear ratio needs to be measured. We measure this at least twice to be 100% sure. The gear ratio is 3.21. This can even be typed manually into the dyno software at a later date.

When you are operating a dyno a scientific operation is a good gesture to make sure that the results can be compared. After the first three runs we see that the power output is always nearly the same. A good sign, here is the best result:

Nice to see that the engine starts to lift the power low down in the rev range. As expected from the Polini kit. A quick road test shows that is a treat to use on the street. At slightly higher idle revs of 3.500 rpm the engine pushes -thanks to 17 Nm- heavily.

The inlet induction sound is nice too. The Polini solution works not just power wise, it reduces induction sound as well. The adapter has a small collar built in that breaks up the acoustic wave what gives a very discret induction sound.

Back from the road testing to the dyno, we take a closer look to the head design. Next we are going to test the MMW head. The previous fitted worb head gave a squish clearance of 1.7mm. To achieve this with the MMW head we are going to fit a 0.7mm head gasket. One quick note: Never combine normal head gasket with O-rings on heads. This doesn't work on the road. For short testing on the dyno it can be done though. And we needed to do this to make the heads test comparable with the same squish clearance.

After some more runs we have a direct comparison of the heads:

RED: MMW

BLUE: Worb5

The higher power output of the MMW head is caused by the slightly higher (but still road safe) compression ratio and the difference in the combustion chamber design.

The highest torque reading is still at 4700 rpm, but rises to a very good 22 Nm. At 7k rpm we still have 17 hp and 17 Nm. God figures for high speed motorway use.

The 60mm MMW head we are not going to test anymore. Not because we are lazy, it is more because there is no sense in it all. We already saw that the higher compression works. the 60mm version would reduce this, so we are not to keen to lose power.

A wider power band with a little more peak power at high revs would be nice though. This really separates good road engines from the very fast ones that are hard to catch on open roads.

Well ... what could be done. Something like a luxury problem here. A good working engine with nice power output in a useable rev range and we are still thinking of how it could be improved.

There it is our MBgm Vespa BIG BOX. Sounds like fun to get this on the Polini. Doesn't it?

This should be done tomorrow!

Stay tuned!

Only a few steps left untill we can dyno test our new engine.

The engine will go into the Silver Fern and be tested for Rally going and daily commuting then.

While fitting the flywheel care must have been taken that the slot in the flywheel cone aligns with the woodcall key.

Afterward the flywheel groove can be tightened down to 65Nm. the washer needs to be fitted, otherwise the nut will come loose.

The rear brake drum goes on the shaft next. We only put it on loose and fix it with the nut.

As soon as the rear brake is adjusted we will tighten it down to 110Nm. Securing cage and splint must be there.

For adjusting the clutch you need a little bit play at the clutch lever. This should be around 1.5mm and 2mm.

Oil and fuel hose are connected. consequences. The air bubble at the oil hose is a very good indication to see if there is oil pumped into the carb.

But the air bubble shouldn't be much bigger than that. Otherwise there is the risk that the oil pump runs dry. And so will do the lubrication then.

For the first firing we fill the fuel tank up with 1 liter of oil petrol mixture of 4%. This should be done to have a proper lubricated engine from the start and to compensate the oil pumps delay.

The engine starts and we let it idle for a while. Then we see that all cables are connected properly. We round down to fourth and everything is okay. The clutch works perfect. And the oil pump operates as well.

So we are ready for the first dyno sessions. Watch this space.

Today we found the time to have a look at the port timings of the Polini kit.

With a 1mm base gasket one look at the degree disc shows us transfer port timings of 125 ° and exhaust timing of 172 °. This results in a blow down timing of 23.5 °.

Figures that really worth to try on the dyno and figures that should result in fast road engine with torque capable of raching high revs for good speed.

We have three different cylinder head designs to test on the engine. And this will be the first mod on the dyno.

We are going to try the MMW for 57mm stroke, the MMW for 60 mmstroke as well as that Worb5 head for 57mm stroke.

On a first sight at the head we have a look at the squish clearance. The MMW 57mm version is a little bit tight at our 60mm crank. The squish would be 1mm on our setup, but well worth to try it with an additional head gasket. The MMW head for 60mm stroke is designed with a recess for the longer stroke. Used with our 1mm base gasket to achieve the right port timings we have a squish clearance of 2.7mm. So we have this head as an option if we want to try the setup without the base gasket. If we don't use the base gasket anymore, the port timings are lowered, but with the effect that the blow down timing is increasing. This is because of the greater reduction of transfer timing compared to the exhaust timing.

The Worb5 head is machined for the 57mm stroke, but with more squish clearance machined into the head. So we have a very useable squish clearance of 1.7 mm without additional head gasket.

The different combustion chamber designs we will test on the dyno the next days. Can't wait!

But the carb is still waiting for fitment. And there are some important steps on the way to take care off.

First of all you have to be careful with the use of sealer. On self-lubrication Vespas the hole marked red in the picture feeds crankshaft, barrel and flywheel side bearing wih oil. If this is blocked no oil gets in and the trouble free miles will be very limited.

The very basic design of the SI carb range is very solo. But one to watch out for is the mounting of the carb, this can easily be destroyed.

If the nuts are over tightened the carb is warped and a sticking slide is the result of it. At least the later version of the SI carb is improved in this area and the nuts can't bend the carb so that the slide sticks.

The pictures shows this feature on the later carbs and this recess can easily be done to later SI carbs.

But even on the later version the carb nuts shouldn't be tightened not more than 16-18Nm. And they shouldnot be fully tightened from the start. Instead tighten they evenly and in turn.

For the carb mounting there are two different versions available as well.

The “old” version with studs and sleeve nuts are there untill the SI carb was used first. the new version was introduced with self lubrication P-ranges labeled EFL, Arcobaleno or Lusso.

The ida came up because this was easier to fit. Carbs without self-lubrication are fitted with a very long air adjuster screw and slide hook.

Before the carb is fitted into it box we cut a slot into the air adjuster screw this makes adjustment much easier on a later point.

Damn, we spoil it!

That happens too often. So you have to take care that the hook hits the clip of the oil pump.

If the carb is fitted like the one pictured, it simply won't work and you foul the slide hook.

Studs for carb fitment are not supporting good work flow and Piaggio introduced the sleeved screw. But this advantage brings a risk.

The screw next to the end of the scoots is located right above the rotary valve.

If you don't use the right washer and spring washer the rotary valve surface will be destroyed for sure.

Tighten it down in steps of 8, 12, 16 Nm.

The Polini bellmouth is secured by only one screw. The idle adjustment screw can be used to get the location of the glory hole right. So simply adjust it that idle adjustment screw and the hole align.

For the dyno sessions we simply screw it to the carb. When all the jetting is done and we are happy with it, we glue the screw into place with threadlock.

The stator plate is adjusted to 18 °. This equals to the “IT” marking on the plate.

Carb and rotary valve inlet are prepared and ready!

Now the bare casings can be filled up with all the internals that make a good engine.

For the gear box we opted for a complete one P200 gearbox with layshaft, pre-assembled and in Original Equipment Manufacturer quality. Not a good idea to cut corners here. Because it is pre-assembled only, we dismantle it, double check it and re-fit it with attention to the gear box play.

To hold it properly in place, we fit the gearbox cruciform with a drop of threadlock.

Gear wheels, securing clip and gear wheels, Seeger and the gear box shims look like this when assembled.

The gear box needs to be shimmed properly. Otherwise problems will occur. The right tolerance is 0.05mm-0.15mm. The best way to check if everything is spot on, is to use two feeler gauges. For new shims you should go for the tighter tolerances. The surface wears much more than with shims that were already used for a few thousand kilometers.

The easiest and best way to fit the inner track of the flywheel bearing is to use the proper tool for it.

Now we are ready to get it bearing kit fitted to the engine casings. The only proper way is to heat the casing or freeze the bearings or even better do both. If this is done fitting is a job that could be done in the kindergarten.

To safe time we cooled the bearings down with ours cooling spray.

The exception to the rule are the small needle bearings. Those should be fitted with the right tool also.

The flywheel side bearing should be guided with the right tool for the job.

For the B188bearing it is a good idea to consult a good one to persuade to get it properly fitted into place.

When you have the bearings in place, there is the time to get the oil seal set fitted.Normally fitting the oil seal shouldn't disturb the work flow too much. Much more patience is needed to get the bearing needles of the Christmas tree in place. To give each needle a good smear whih a nice grease helps very much here. Every needle should be counted and the end result needs to be 21.

The Kick start sprocket and Shaft are the only parts remaining at the workbench, while the engine is waiting for those.

One to watch! Don't forget to fit the kick start spring, holding it in place with some grease is advisable.

Now the crank is fitted and the casing halves can be put together.

The engine casing studs are torqued down evenly.

The oil gear drive is fitted.

The drive wheel has one washer on each side. At the picture there is only that securing ring missing that holds the wheel tightly in place.

After the oil pump wheel is fitted with the fine smear of oil, the Fort can be put onto the crank. There is a chamfered side at the wheel, this side should face forward to the engine casing. Otherwise the whhel and crank could touch. Mainly depending on the crank design.

Once fitted you can see the beauty and nice design of the bgm crankshaft together with double lipped oil seal.

One of the most important things is to get the power of the top end transmitted to the bottom end. Therefore we highly recommend the well proved bgm Superstrong clutch.

Design to be used with 10 clutch springs there are plenty of variations to cope with any power!

For the expected power delivery we opt for 10 XL springs.

Once again: oil! This time to lubricate wave designed hub.

Now we are going to fit the clutch sprocket and clutch plates. If you are going to purchase a complete bgm SUPERSTRONG all this will be done for you. And you receive a complete plug & play unit.

For first fit some drops of oil will do it!

For the steel plates the positining of the curved one is of importance.

This one needs to be slightly bent, only a few tenths of a millimeter to get the clutch working properly right from the start of the lever action.

If the plates, steel plates and securing clip are fitted it is done.

The self-locking n is tightened to 60Nm.

Once the engine is completed, the proper tuning action can start. Tomorrow we are going to have a look for the port timings!

Today we took a closer look at the Air intake filter / bellmouth from Polini as well as for that Dell Orto SI 26 carbs And we will answer the question what the glory hole on top of the carb is good for?

In the end it has a good effect on the functioning of the carb. Simplified it works like a bigger carb, the carb sucks harder and gives more fresh air for the engine. The result is well known: more power, good!

If your engine gets more air you need to enrich the mixture with the right amount of more fuel. The delivery of the Polini air intake includes a138 main jet for the SI carb (this is at the P200 version).

At the idle jet and atomizer there is a relief groove at the venturi. This guides the fresh air thru. This is similar to the mods done to that SI air filter base. To get a bore in there gives a better and easier jetting and better throttle response. This does the groove in the Polini kit as well.

Because you can't put the air filter on top anymore, Polini found a nice and well working solution for this too.

An adapter kit is tightened down at the carb box. This makes it easily possible to fit a modern day foam filter.

The adapter should be fitted in a way that you can still get to all connectors, fuel pipe connection as well as cables for choke and throttle cable.

The fact that Polini included a 138 main gives a rough indication of how much more air will get thru with this neat mod. Experience on engines with bigger SI main jets than 130 showed us that some mods to the carb are needed to get the show reliable. Otherwise the fuel starvation will happen.

You need to sort this out properly and start where the action starts. At first the fuel tap should deliver enough fuel. We recommend for tuned engines bgm FASTER FLOW taps. These are capable of delivering more than enough fuel. If your fuel tap gets 280-300 ml / min through everything should be fine. But check the video at the fuel tap out to get the full story.

Except for a working air vent in the fuel tap cover you can't do much more for the fuel tank. It is sorted with the bgm FASTER FLOW.

Now we come to the blue printing of the carb that is needed-at least- from 130 main jets on.

The small float bowl of the SI carb needs to be topped up with fuel all the time. Even under full throttle for long distances. The main bottle neck here is the float bowl valve. The best way is to swap this for the Vespa Cosa one. A straight and easy fit that cures this problem.

To the right: the standard SI item. At the left corner: The Cosa one.

Except for the larger float needle the bore diameter for the valve is bigger too. And for sure the of the valve.

The fuel channel for the float valve is opened up to 3mm.

Now all the needed mods are done to have a proper blue printed SI carb that gets enough fuel even on powerful engines.

One hidden design fault is still there though.

The small hole in the middle of the picture has a 1.5mm diameter. This is the channel for the main jet. All the fuel for the main jet has to go through this.

This is too small as well. It is good for a 150 main jet but a design flaw. We drill this out to 2mm. Better safe than sorry!

The bore at the left is for the choke system only and fine as it is.

The battle for the precedence is at the voters. The world is waiting for the results, while we are under the impression that the sympathy seems to be at one of the contrahents.

We have election day today as well and we are waiting excited who did the better green shade? While the late 6Ts brought us innovation like long hair, free love and the said Green apple shade.At Piaggio's Vespa as well as for Innocenti's Lambretta.

Especially the Vespa V50 and the Lambretta SX 150 are rare as rocking horse shit and for that and the stunning looks much sought after.

Here you'll find some pictures of original paint Verde Mela scooters as well as the election for the better shade of it!

[Poll id = "13"]

Lots of scooterists out there and in here Scooter Center to, dream about a Polini 207 kit made of alloy with the hard wearing Nicasil plating. This dream already came true!

we had one of the first kits fitted to a 10 hp standard P-range engine on our P4 dyno. The bullet proof Polini layout was even better in the alloy trim. High torque low down the rev range made it t the most desired kit right from the start.

Polini introduced more and more toys for boys. Lots of stuff to get higher power output and an even bigger grin on your face. Besides the airintake / bellmouth To get the most out of the SI carbs, a Polini 210 kit for 60mm stroke is down in the pipe line. This kit is specially made for the 60mm crank and gives 221 tsp.

With lots of trouble free miles during the last 1 1/2 year we are so happy with the kit that we decided to build a Polini test engine and show you what we think is worth to take care of. As soon as the 60mm version is out, we will replace the 210 for the 221.

The games started today and this is stored into the workshop. And the dyno is waiting desperately.

Cylinder kit Polini 210, cylinder head MMW and Worb5, airintake / bellmouth Polini for SI carbs, 26mm SI carb and one of the bgm PRO 60mm crank.

All parts are carefully checked and everything is going to be prepared for fitting.

First view is the engine casing, that will house all the other toys we saw here.

At the moment the only P 200 casings are branded as Malossi. Besides the name nothing major changed though.

Care we have taken for the inlet area. The inlet area is carefully cleaned, blue orinted and optimized.

For the heart of the engine we opted for the BGM crankshaft. Perfect inlet timing for high power, clean running and good fuel consumption are the key words of the good designed crankshaft. The very well made crank leaves nothing to be desired.

An additional nice feature of the bgm PRO crankshaft is the enlarged sealing area at the taper of the flywheel side. Thanks to this you can use the far superior FPM oil seal with dust lip. Compared to the common NBR oil seals FPM oil seal has a much better reliability.

N Next we will have a look for the Polini air intake improvement. Watch this space!

Polinis project to launch the well known 210cc aluminum cylinder for the PX as a long-stroke version (as reported), is finally in the last steps.

The new cylinder, which is presumably similar to the existing 210cc cylinder (but with a long aluminum bore), will be available with a special cylinder head to fit the stroke of 60mm. For further details such as steering angle, compression and performance data we will keep you posted as these information are not known yet.

The new cylinder, which is presumably similar to the existing 210cc cylinder (but with a long aluminum bore), will be available with a special cylinder head to fit the stroke of 60mm. For further details such as steering angle, compression and performance data we will keep you posted as these information are not known yet.

The cylinder head will also be available separately. According to Polini this head will also fit the existing aluminum and cast iron versions with standard stroke. We will see how this is achieved and what head will look like.

The performance of the current 57mm stroke aluminum version can be found in our earlier blog reports here:

A special self-made long-stroke version has been tested here:

We expect that the new version will have an even broader performance than the 210cc variant, as the angle bound will automatically grow through the use of a 60mm stroke crankshaft. This would certainly result in an engine concept for everyday use with lots of torque from low engine speeds, a strong middle performance and a sufficient rotary power for the highway. All without the balancing act of the old thermal cast iron version.

We expect that the new version will have an even broader performance than the 210cc variant, as the angle bound will automatically grow through the use of a 60mm stroke crankshaft. This would certainly result in an engine concept for everyday use with lots of torque from low engine speeds, a strong middle performance and a sufficient rotary power for the highway. All without the balancing act of the old thermal cast iron version.

Polini also wants to offer an own designed crankshaft for this cylinder kit:

Polini speaks of a well balanced shaft. Here again, we will post all further information as soon as we receive it and have verified it ourselves.. The suggested retail price of Polini is around 290Euro

Polini speaks of a well balanced shaft. Here again, we will post all further information as soon as we receive it and have verified it ourselves.. The suggested retail price of Polini is around 290Euro

The cylinder will of course also run on any 60mm stroke crank. A high quality and significantly less expensive alternative is our bgm PRO crankshaft which has been proven in quite a few very powerful engines

With a selling price of 179,99 € our bgm crank it will be much cheaper than the polini version but regarding quality it will be similar and has proven its power already in many existing setups.

Conclusion: Polini makes again a big step forward regarding its leadership in terms of product innovations in the kickstart scooter market. While rival Malossi currently limits their ideas to changing names of already existing products, Polini shows what they can provide with a little more courage and innovative spirit.

The selling price of the new cylinder will be a little higher than the current one 210cc cylinders as the head will be included in the new kit.

Cylinder and shaft together will offer a strong touring package that will probably have around 20hp.

What do you need more?

Surely one of the loveliest inventions for the PX200 since our BGM Superstrong Cosa clutch...