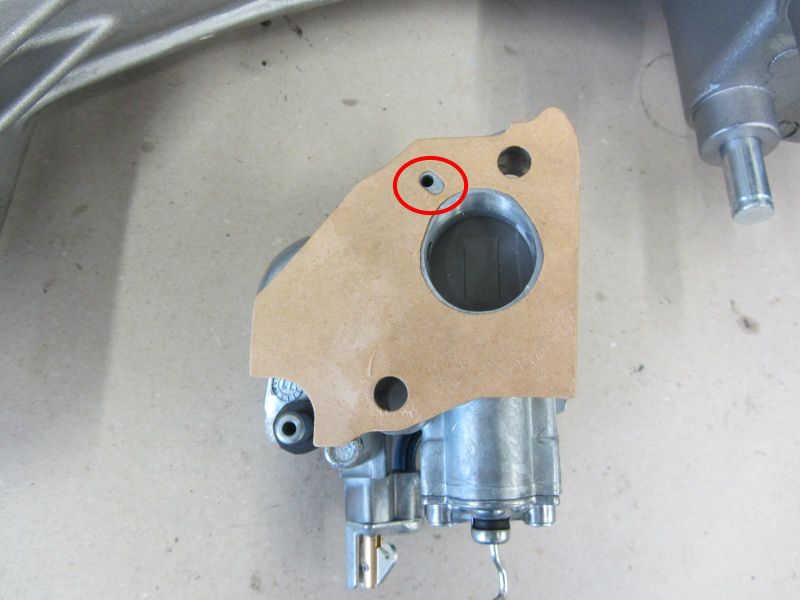

Carb and rotary valve inlet are prepared and ready!

Now the bare casings can be filled up with all the internals that make a good engine.

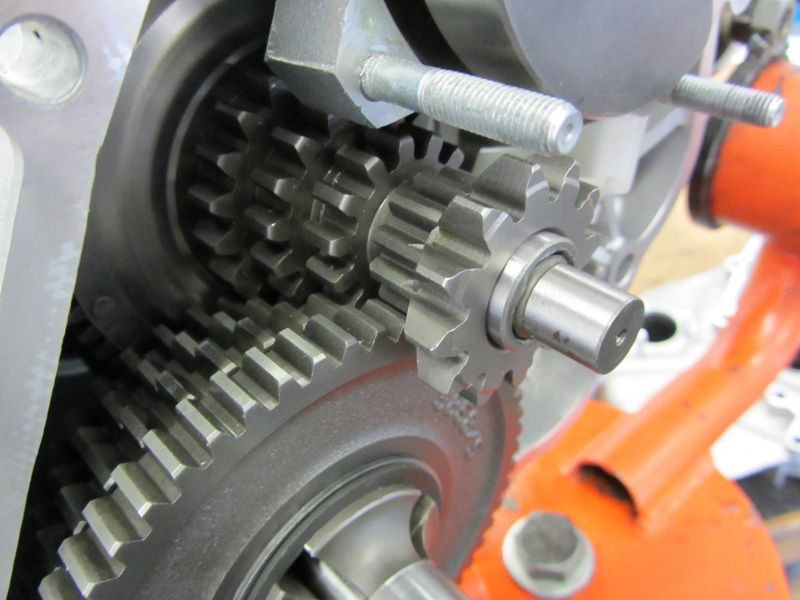

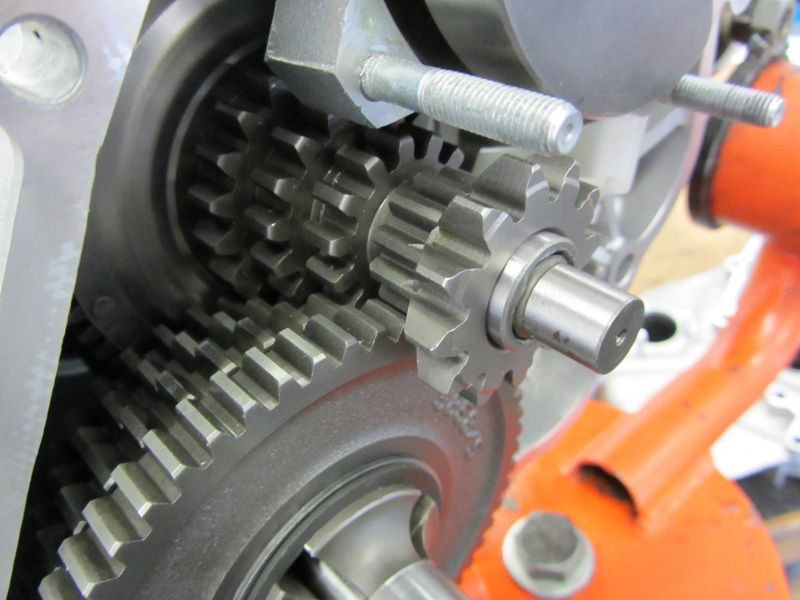

For the gear box we opted for a complete one P200 gearbox with layshaft, pre-assembled and in Original Equipment Manufacturer quality. Not a good idea to cut corners here. Because it is pre-assembled only, we dismantle it, double check it and re-fit it with attention to the gear box play.

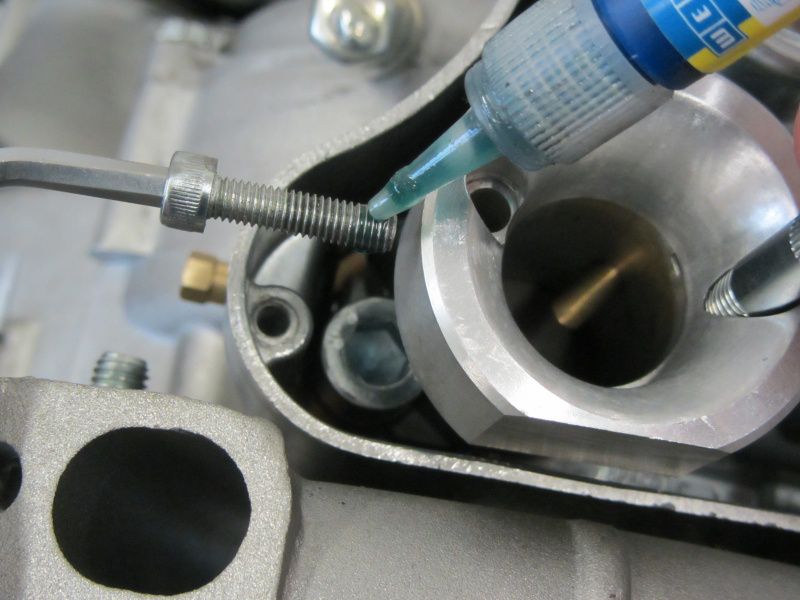

To hold it properly in place, we fit the gearbox cruciform with a drop of threadlock.

Gear wheels, securing clip and gear wheels, Seeger and the gear box shims look like this when assembled.

The gear box needs to be shimmed properly. Otherwise problems will occur. The right tolerance is 0.05mm-0.15mm. The best way to check if everything is spot on, is to use two feeler gauges. For new shims you should go for the tighter tolerances. The surface wears much more than with shims that were already used for a few thousand kilometers.

The easiest and best way to fit the inner track of the flywheel bearing is to use the proper tool for it.

Now we are ready to get it bearing kit fitted to the engine casings. The only proper way is to heat the casing or freeze the bearings or even better do both. If this is done fitting is a job that could be done in the kindergarten.

To safe time we cooled the bearings down with ours cooling spray.

The exception to the rule are the small needle bearings. Those should be fitted with the right tool also.

The flywheel side bearing should be guided with the right tool for the job.

For the B188bearing it is a good idea to consult a good one to persuade to get it properly fitted into place.

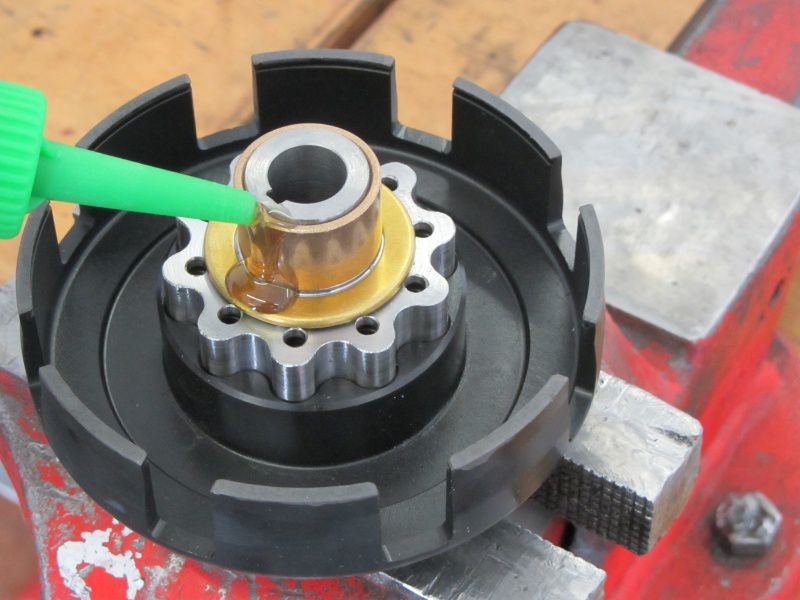

When you have the bearings in place, there is the time to get the oil seal set fitted.Normally fitting the oil seal shouldn't disturb the work flow too much. Much more patience is needed to get the bearing needles of the Christmas tree in place. To give each needle a good smear whih a nice grease helps very much here. Every needle should be counted and the end result needs to be 21.

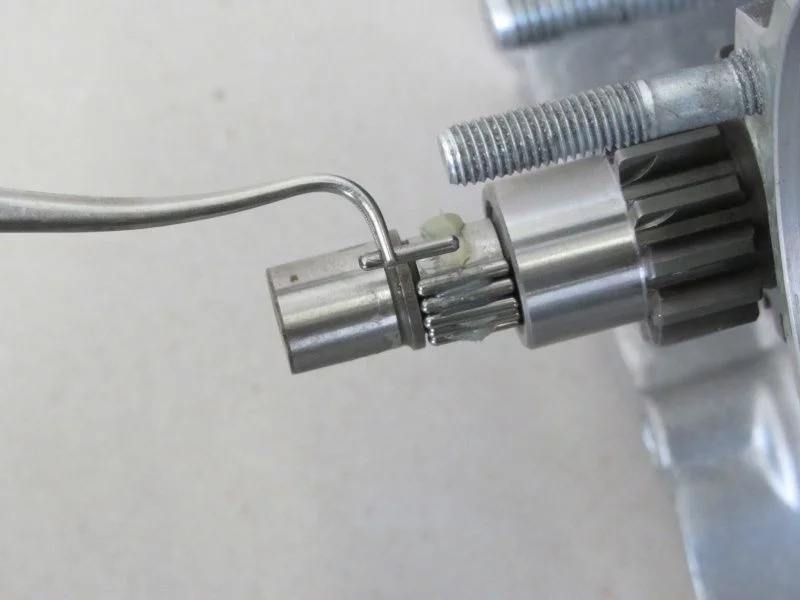

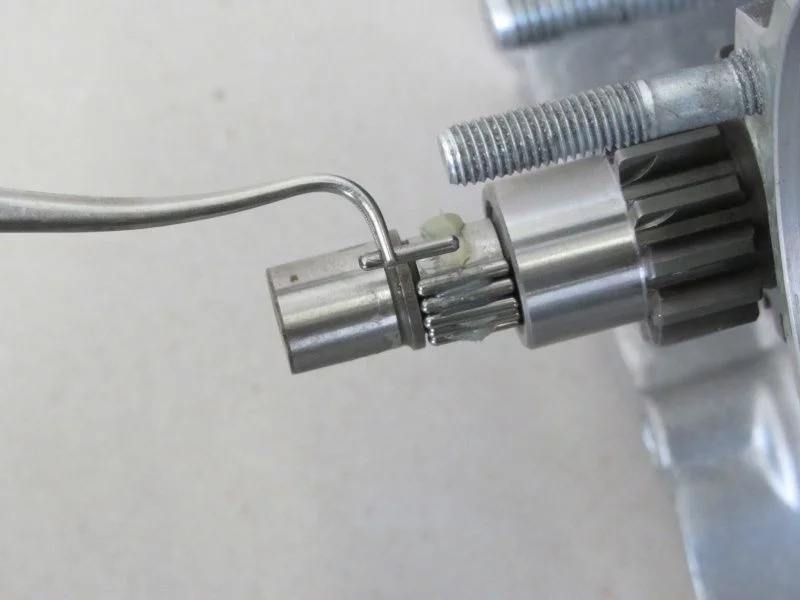

The Kick start sprocket and Shaft are the only parts remaining at the workbench, while the engine is waiting for those.

One to watch! Don't forget to fit the kick start spring, holding it in place with some grease is advisable.

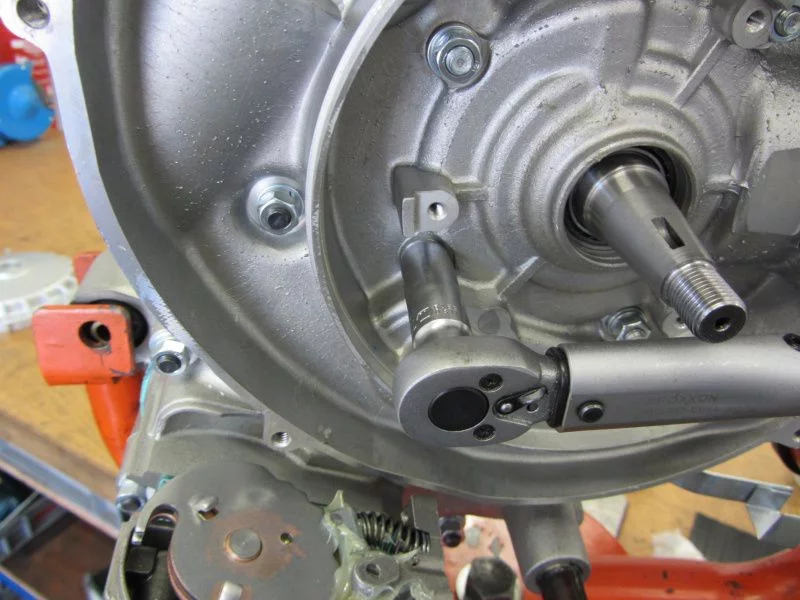

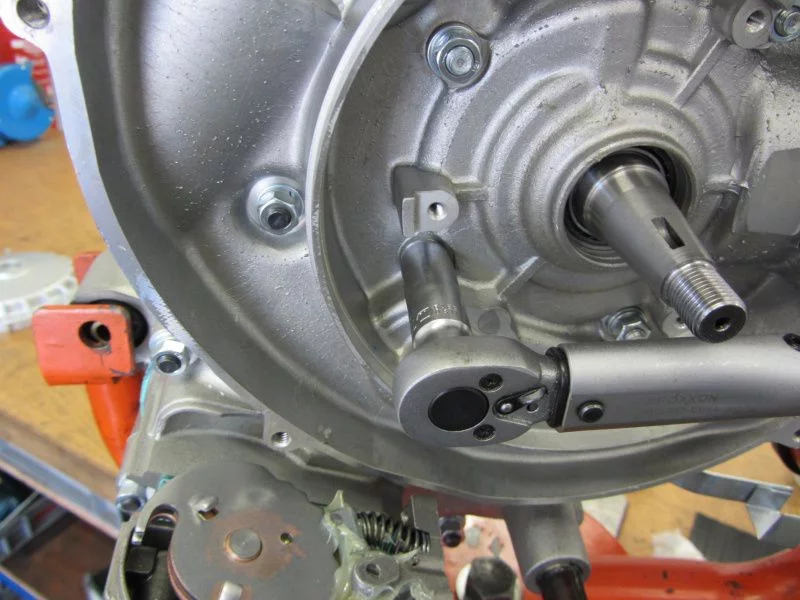

Now the crank is fitted and the casing halves can be put together.

The engine casing studs are torqued down evenly.

The oil gear drive is fitted.

The drive wheel has one washer on each side. At the picture there is only that securing ring missing that holds the wheel tightly in place.

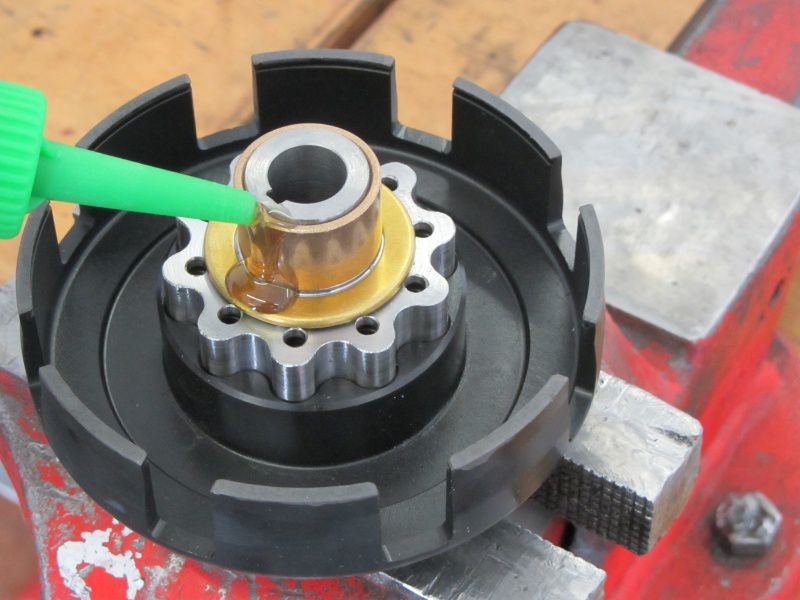

After the oil pump wheel is fitted with the fine smear of oil, the Fort can be put onto the crank. There is a chamfered side at the wheel, this side should face forward to the engine casing. Otherwise the whhel and crank could touch. Mainly depending on the crank design.

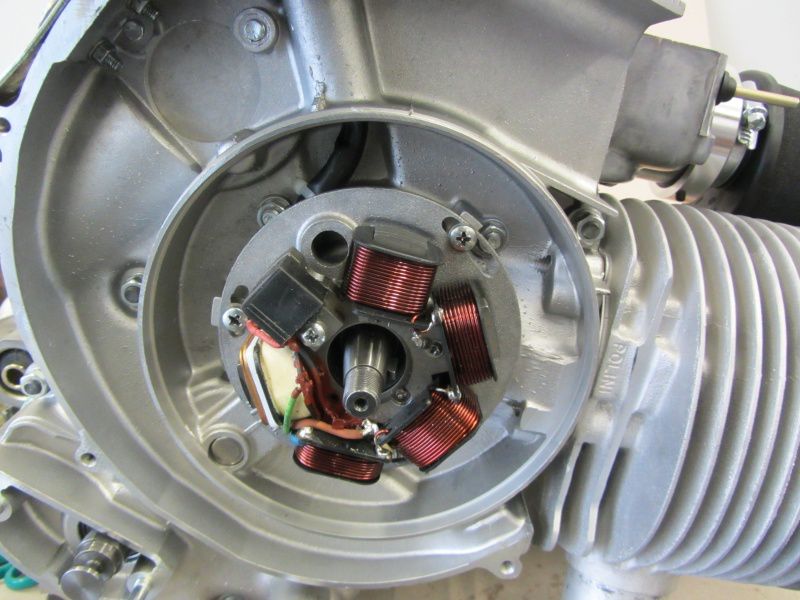

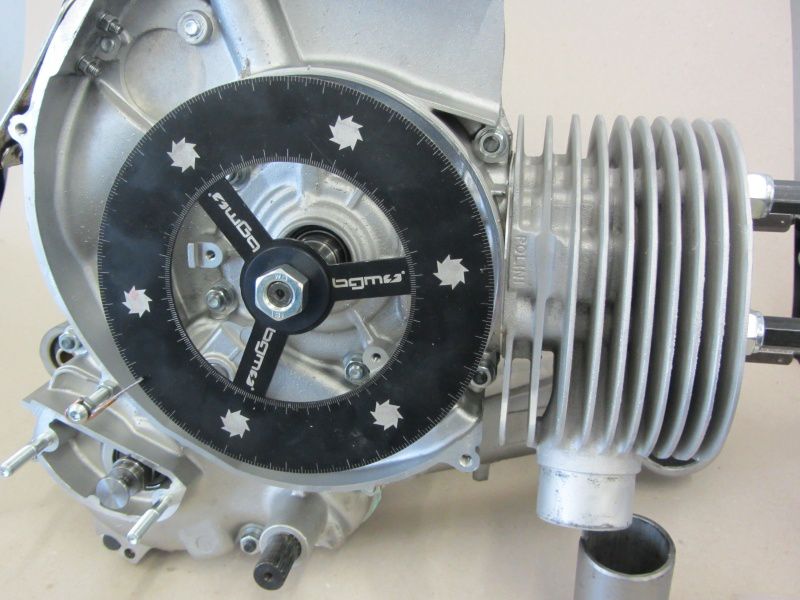

Once fitted you can see the beauty and nice design of the bgm crankshaft together with double lipped oil seal.

One of the most important things is to get the power of the top end transmitted to the bottom end. Therefore we highly recommend the well proved bgm Superstrong clutch.

Design to be used with 10 clutch springs there are plenty of variations to cope with any power!

For the expected power delivery we opt for 10 XL springs.

Once again: oil! This time to lubricate wave designed hub.

Now we are going to fit the clutch sprocket and clutch plates. If you are going to purchase a complete bgm SUPERSTRONG all this will be done for you. And you receive a complete plug & play unit.

For first fit some drops of oil will do it!

For the steel plates the positining of the curved one is of importance.

This one needs to be slightly bent, only a few tenths of a millimeter to get the clutch working properly right from the start of the lever action.

If the plates, steel plates and securing clip are fitted it is done.

The self-locking n is tightened to 60Nm.

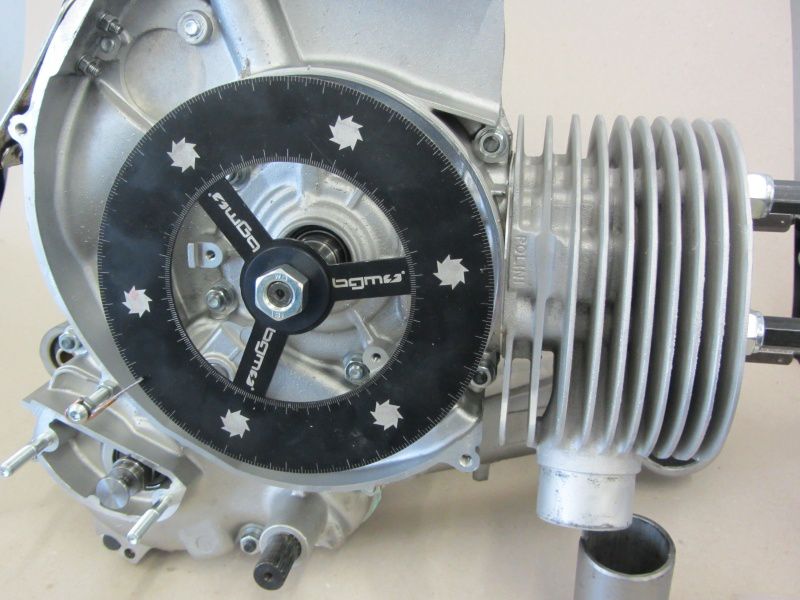

Once the engine is completed, the proper tuning action can start. Tomorrow we are going to have a look for the port timings!